Welcome to Your System Partner for Drive and Damping Technology

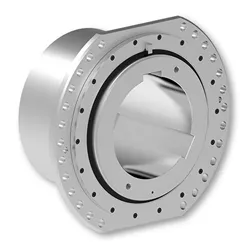

RINGFEDER POWER TRANSMISSION is the international market leader in niche markets for drive and damping technology. We develop, manufacture and supply superior Shaft-Hub Connections, Damping Components, Couplings, Brake Systems and Bearing Housings for highest functionality and durability requirements in a wide range of technology sectors worldwide.

We not only always provide our ambitious customers with competent advice based on over 100 years of experience and expertise, but also realize need-based, application-oriented solutions together with them that guarantee safe, failure-free and economic machine and plant operation – with our aspiration to

be Partner for Performance.

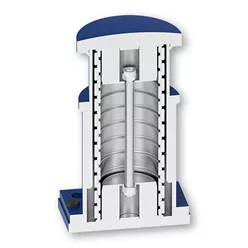

Coupling-Brake Systems RINGFEDER® TZ

RINGFEDER POWER TRANSMISSION is pleased to announce it has acquired the industrial brake business of TÜSCHEN & ZIMMERMANN GMBH & CO. KG. This acquisition will provide our customers with access to advanced industrial braking solutions that perfectly complement our current product portfolio, further strengthening our market position as one of the leading partners for systems and components of drive and damping technology.

Our High-Quality Product Portfolio

Product Guide RINGFEDER®

First-class Shaft-Hub Connections, Damping Components, Couplings and Coupling-Brake Systems for highest requirements in a wide variety of applications – get a quick and easy overview of RINGFEDER POWER TRANSMISSION as well as all product lines and series of our premium brand RINGFEDER® with our latest comprehensive Product Guide.

Learn More About Our Application Segments

The Engineer's Blog

Recent technological innovations, latest industry news, smart solution concepts and in-depth practical reports – stay well informed about our world of drive and damping technology.

Locking Assemblies Optimize Shredder Performance for Sustainable Farming

Shredding machines are more and more used by farmers in countries like India. Many farmers burn the crop residues in...

Read MoreWhat Can Vibration Dampers Do for Earthquake-Resistant Construction?

Effective, easy to install, cost-efficient: Vibration dampers are ideal for dissipating earthquake-induced energy fro...

Read MoreRINGFEDER® in the Entertainment Industry: Our Connection with a T-Rex

We manufacture products that comply with the highest function and safety requirements set forth in the most diverse...

Read MoreYour Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.