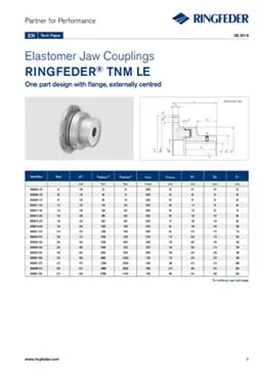

Elastomer Jaw Couplings TNM LE

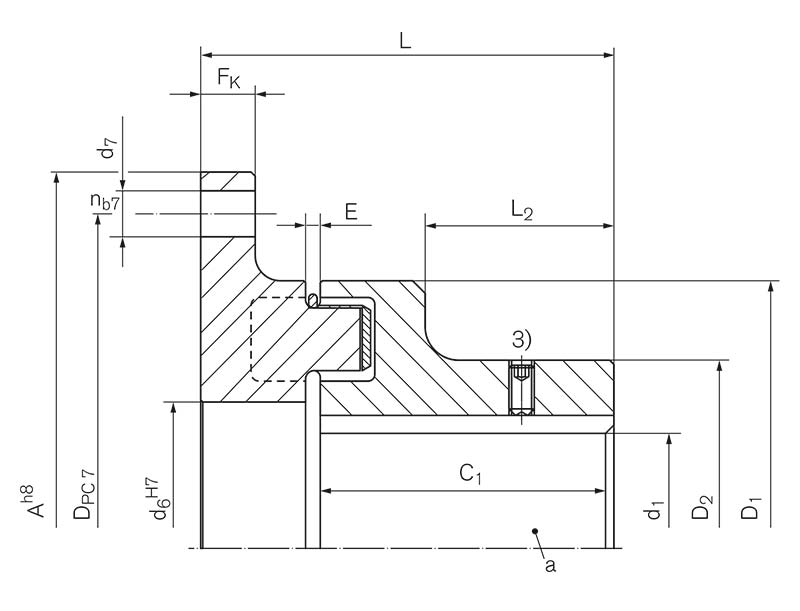

One part design with flange, externally centred

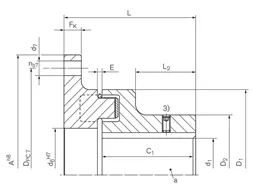

The RINGFEDER® TNM LE is a torsionally elastic and puncture-proof jaw coupling with screw-down flange. It balances out angular, radial and axial shaft offset within determined tolerances. The coupling transmits the torque via pre-compressed, elastic buffers in synthetic rubber (Perbunan; Pb) that are connected to one another into an intermediate ring. The elastic intermediate ring in synthetic rubber (Perbunan; Pb) damps impacts and torsional vibration and is electrically conductive, so that undesired static charging is avoided. The coupling can be used in any direction of rotation and installation position.

Technical Data & CAD Models

| CAD |

Identifier

|

A

mm |

TKNPb82

Nm |

nmax

1/min |

d1kmax

mm |

D1

mm |

C1

mm |

FK

mm |

DPC7

mm |

nb7

|

d7

mm |

L

mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WN0806-106 | 106 | 35 | 5000 | 28 | 67 | 30 | 8 | 94 | 6 | 6,6 | 47,5 | |

| WN0808-120 | 120 | 75 | 5000 | 32 | 82 | 40 | 8 | 108 | 6 | 6,6 | 59 | |

| WN0809-144 | 144 | 150 | 5000 | 45 | 97 | 50 | 10 | 128 | 6 | 9 | 73 | |

| WN0811-158 | 158 | 230 | 5000 | 48 | 112 | 60 | 10 | 142 | 6 | 9 | 85,5 | |

| WN0812-180 | 180 | 380 | 5000 | 55 | 128 | 70 | 13 | 160 | 6 | 11 | 98,5 | |

| WN0814-200 | 200 | 600 | 4500 | 65 | 148 | 80 | 13 | 180 | 7 | 11 | 111,5 | |

| WN0816-220 | 220 | 980 | 4000 | 75 | 168 | 90 | 13 | 200 | 8 | 11 | 127,5 | |

| WN0819-248 | 248 | 1650 | 3500 | 85 | 194 | 100 | 16 | 224 | 8 | 14 | 141,5 | |

| WN0821-274 | 274 | 2400 | 3000 | 95 | 214 | 110 | 16 | 250 | 8 | 14 | 156 | |

| WN0824-314 | 314 | 3700 | 2750 | 110 | 240 | 120 | 20 | 282 | 8 | 18 | 169 | |

| WN0826-344 | 344 | 5800 | 2500 | 120 | 265 | 140 | 20 | 312 | 8 | 18 | 195,5 | |

| WN0829-380 | 380 | 7550 | 2250 | 130 | 295 | 150 | 22 | 348 | 9 | 18 | 210 | |

| WN0833-430 | 430 | 9900 | 2000 | 150 | 330 | 160 | 25 | 390 | 9 | 22 | 224 | |

| WN0837-480 | 480 | 14000 | 1750 | 170 | 370 | 180 | 25 | 440 | 10 | 22 | 250 | |

| WN0841-575 | 575 | 20500 | 1500 | 190 | 415 | 200 | 30 | 528 | 10 | 26 | 273 | |

| WN0848-615 | 615 | 28000 | 1400 | 210 | 480 | 220 | 30 | 568 | 10 | 26 | 293 | |

| WN0857-692 | 692 | 41000 | 1200 | 230 | 575 | 240 | 30 | 645 | 10 | 26 | 313 |

| CAD |

Identifier |

A inch |

TKNPb82 ft-lbs |

nmax rpm |

d1kmax inch |

D1 inch |

C1 inch |

FK inch |

DPC7 inch |

nb7 |

d7 inch |

L inch |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WN0806-106 | 4.173 | 26 | 5000 | 1.10236 | 2.638 | 1.181 | 0.315 | 3.701 | 6 | 0.260 | 1.870 | |

| WN0808-120 | 4.724 | 55 | 5000 | 1.25984 | 3.228 | 1.575 | 0.315 | 4.252 | 6 | 0.260 | 2.323 | |

| WN0809-144 | 5.669 | 111 | 5000 | 1.77165 | 3.819 | 1.969 | 0.394 | 5.039 | 6 | 0.354 | 2.874 | |

| WN0811-158 | 6.220 | 170 | 5000 | 1.88976 | 4.409 | 2.362 | 0.394 | 5.591 | 6 | 0.354 | 3.366 | |

| WN0812-180 | 7.087 | 280 | 5000 | 2.16535 | 5.039 | 2.756 | 0.512 | 6.299 | 6 | 0.433 | 3.878 | |

| WN0814-200 | 7.874 | 443 | 4500 | 2.55905 | 5.827 | 3.150 | 0.512 | 7.087 | 7 | 0.433 | 4.390 | |

| WN0816-220 | 8.661 | 723 | 4000 | 2.95275 | 6.614 | 3.543 | 0.512 | 7.874 | 8 | 0.433 | 5.020 | |

| WN0819-248 | 9.764 | 1217 | 3500 | 3.34645 | 7.638 | 3.937 | 0.630 | 8.819 | 8 | 0.551 | 5.571 | |

| WN0821-274 | 10.787 | 1770 | 3000 | 3.74015 | 8.425 | 4.331 | 0.630 | 9.843 | 8 | 0.551 | 6.142 | |

| WN0824-314 | 12.362 | 2729 | 2750 | 4.3307 | 9.449 | 4.724 | 0.787 | 11.102 | 8 | 0.709 | 6.654 | |

| WN0826-344 | 13.543 | 4278 | 2500 | 4.7244 | 10.433 | 5.512 | 0.787 | 12.283 | 8 | 0.709 | 7.697 | |

| WN0829-380 | 14.961 | 5569 | 2250 | 5.1181 | 11.614 | 5.906 | 0.866 | 13.701 | 9 | 0.709 | 8.268 | |

| WN0833-430 | 16.929 | 7302 | 2000 | 5.9055 | 12.992 | 6.299 | 0.984 | 15.354 | 9 | 0.866 | 8.819 | |

| WN0837-480 | 18.898 | 10326 | 1750 | 6.6929 | 14.567 | 7.087 | 0.984 | 17.323 | 10 | 0.866 | 9.843 | |

| WN0841-575 | 22.638 | 15120 | 1500 | 7.4803 | 16.339 | 7.874 | 1.181 | 20.787 | 10 | 1.024 | 10.748 | |

| WN0848-615 | 24.213 | 20652 | 1400 | 8.2677 | 18.898 | 8.661 | 1.181 | 22.362 | 10 | 1.024 | 11.535 | |

| WN0857-692 | 27.244 | 30240 | 1200 | 9.0551 | 22.638 | 9.449 | 1.181 | 25.394 | 10 | 1.024 | 12.323 |

Images & Drawings

Product Characteristics

Elastomer Jaw Coupling RINGFEDER® TNM

RINGFEDER® TNM jaw couplings can be used universally in general engineering and are primarily utilised as drive and output couplings for gears, in pumps and screw compressor drives as well as in combined heat and power plants.

Advantages

- Torsionally flexible

- Damping of torsional vibrations

- Blind connection

- Many variations with modular design

- Individual elastomers joined to one intermediate ring

- Max. Torque: 27 – 97500 Nm

- Easy replacement of elastomers

Characteristics TNM LE

- Torsionally flexible, compensate for angular, radial and axial shaft misalignment

- Pre-compressed individual buffers connected to an inter- mediate ring

- Intermediate rings of different Shore hardness levels (standard Pb72, hard Pb82), can be used from –30 °C to +100 °C

- Changing of the elastic intermediate ring with movement of the connected aggregates

- Bores up to 230 mm

- Torques up to TKn = 41000 Nm / TKmax = 97500 Nm

- Speeds up to nmax = 5000 min-1

Basic information

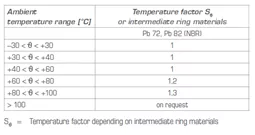

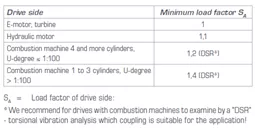

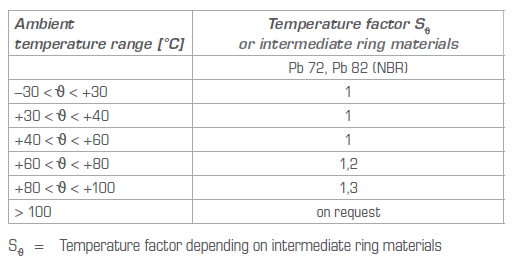

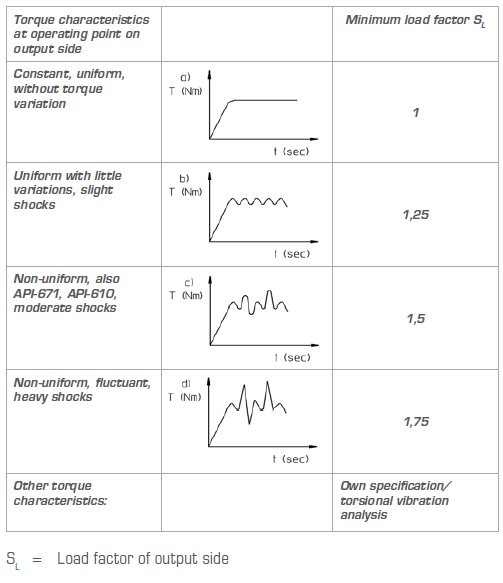

Intermediate rings are available in two different material hardness levels (Pb72 and Pb82) for each coupling size. The harder the intermediate ring the higher the transmittable torque but also the higher the torsion spring stiffness. The nominal torque given in the data table for the TKN coupling can be transmitted continuously. The maximum coupling torque TKmax can be transmitted briefly up to 105 times, for example as occurs during start-up.

When the hard elastic element of Pb82 is used for multi-part coupling designs, it has to be taken into account that the maximum transmittable torque (TKGmax) is reduced. In these cases, TKmax is limited by the frictional engagement between the coupling hub and the claw ring.

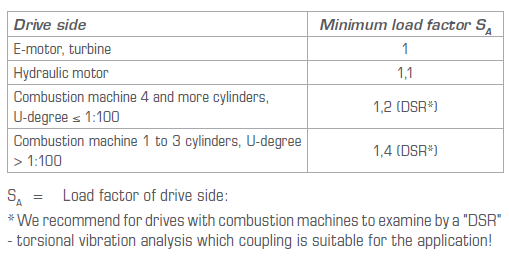

Torsional vibration analyses (TVR) are performed by specialists to optimize the drive line. To this purpose, a detailed description of the oscillatory system is required, including the mechanical arrangement (spring-mass system) as well as the plant-related excitation functions. The specific coupling data such as stiffness, damping and mass moments of inertia will be supplied on request.

Downloads

Product Paper Elastomer Jaw Couplings RINGFEDER® GWE, TNM, TNS, TNB

Tech Paper Elastomer Jaw Couplings RINGFEDER® TNM LE

Instruction Manual Elastomer Jaw Couplings RINGFEDER® TNM LE

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

Downloads