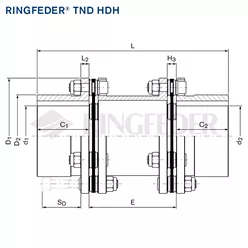

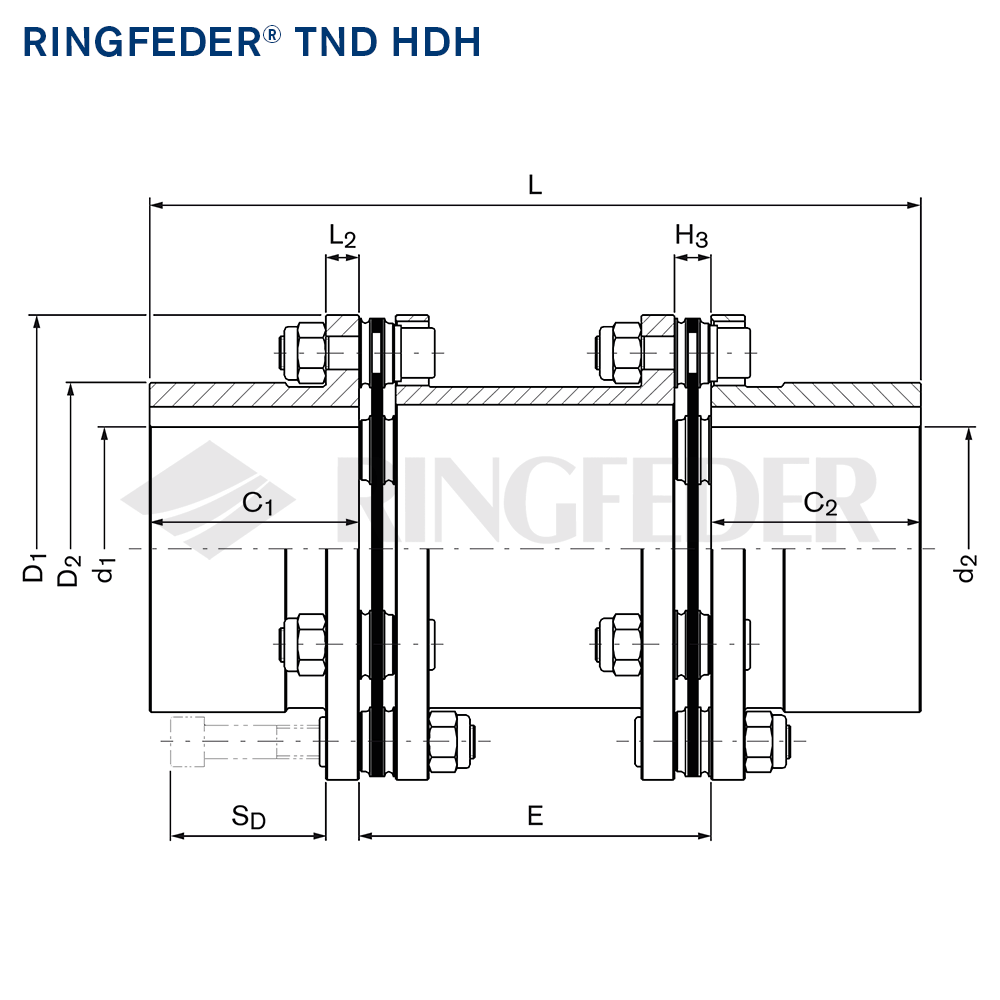

Steel Disc Couplings TND HDH

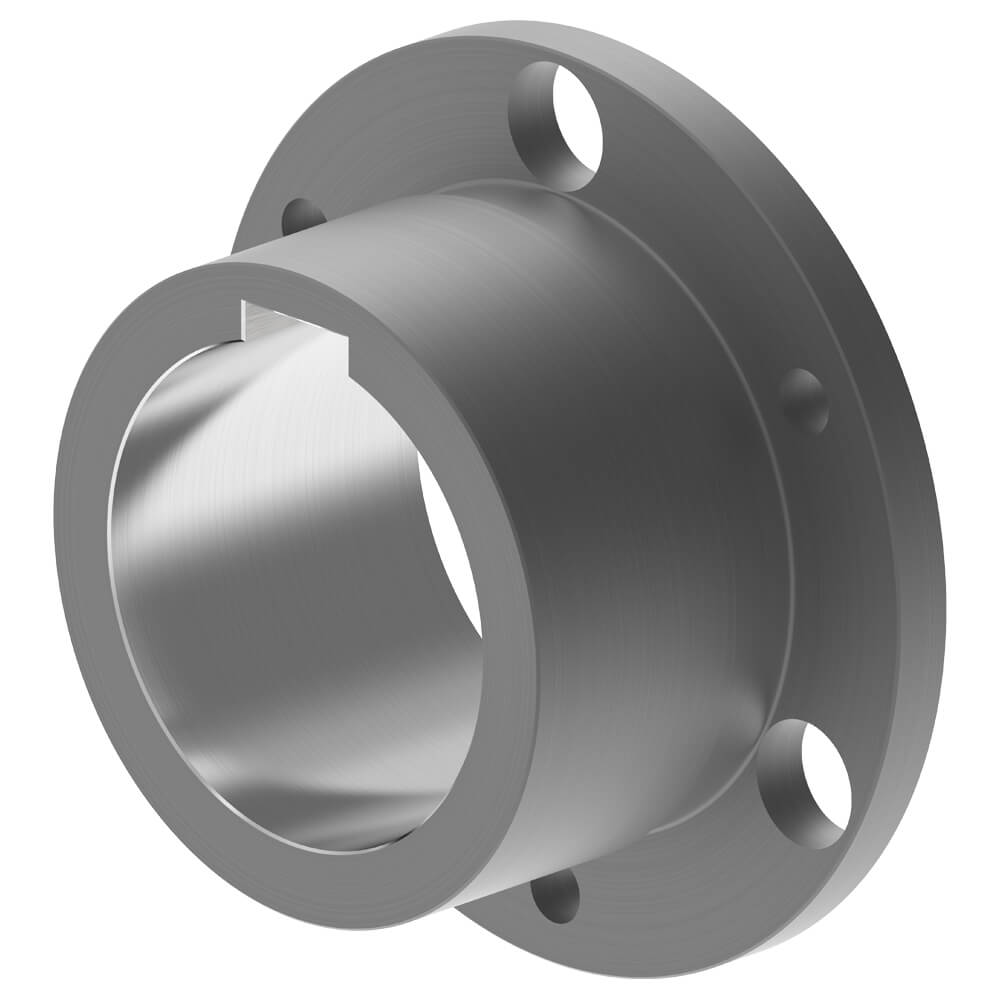

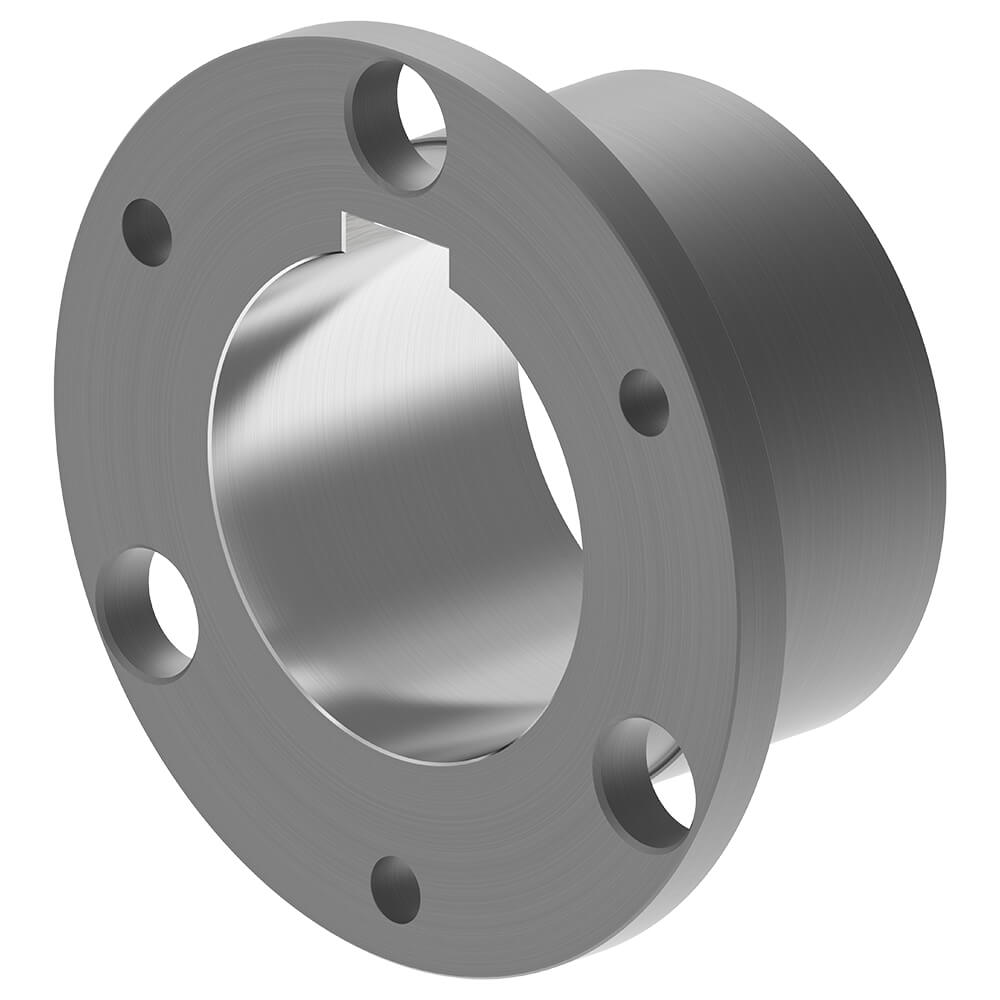

Standard Hubs, Double-Jointed, without Spacer, Shaft-Hub Connection by Keyway according to DIN 6885-1

- 11 Sizes

- Max. Bore Diameter d: 32-215 mm (1.259-8.465 inch)

- Max. Outer Diameter D1: 70.5-510 mm (2.776-20.078 inch)

- Hub Distance E: 60-350 mm (2.362-13.779 inch)

- Overall Length L: 139-830 mm (5.472-32.677 inch)

- Rot. Speed nmax: 1,700-12,200 1/min

- Torque TKN: 170-130,000 Nm (125.36-95,833.07 ft·lb)

Product Characteristics

Your Benefits

The type RINGFEDER® TND HDH is a torsionally stiff, backlash-free steel disc coupling consisting of two standard hubs H as well as a spacer D in standardized or individually customized length. Using high-strength screws, one disc pack each is connected to the spacer and one hub, thus achieving the function of a double-cardanic system.

Depending on the coupling size, two different disc packs are available:

- Type HD (= High Deflection) for increased compensation capability at occurring shaft misalignments.

- Type HT (= High Torque) with larger power density for higher requirements on transmissible torque.

The double-jointed design with two disc packs compensates for radial (adjustable via the spacer length), angular and axial shaft misalignments.

Steel disc couplings of the RINGFEDER® TND HDH type are particularly convincing due to the following features:

- Completely backlash- and maintenance-free

- Highly effective compensation of angular, axial and radial shaft misalignment

- Torsionally rigid with high torsional stiffness

- Low restoring forces in case of shaft misalignment due to optimum disc pack design

- Bridging of large shaft distances by means of spacers in various standard and freely customizable special lengths

- Bore diameter d1/2 up to 215 mm (8.465 inch)

- Transmissible torque TKN up to 130,000 Nm (95,833.07 ft·lb) / Tkmax up to 220,000 Nm (162,263.67 ft·lb)

- Rotational speeds depending on spacer length nmax up to 12,200 1/min

- Efficient realization of customer-specific solutions at short delivery times thanks to modular design

ATEX Compliance

For maximum safety in explosion-endangered areas, RINGFEDER® Steel Disc Couplings can of course be supplied in compliance with ATEX according to Product Directive 2014/34/EU and DIN EN ISO 80079-36:2016 if required.

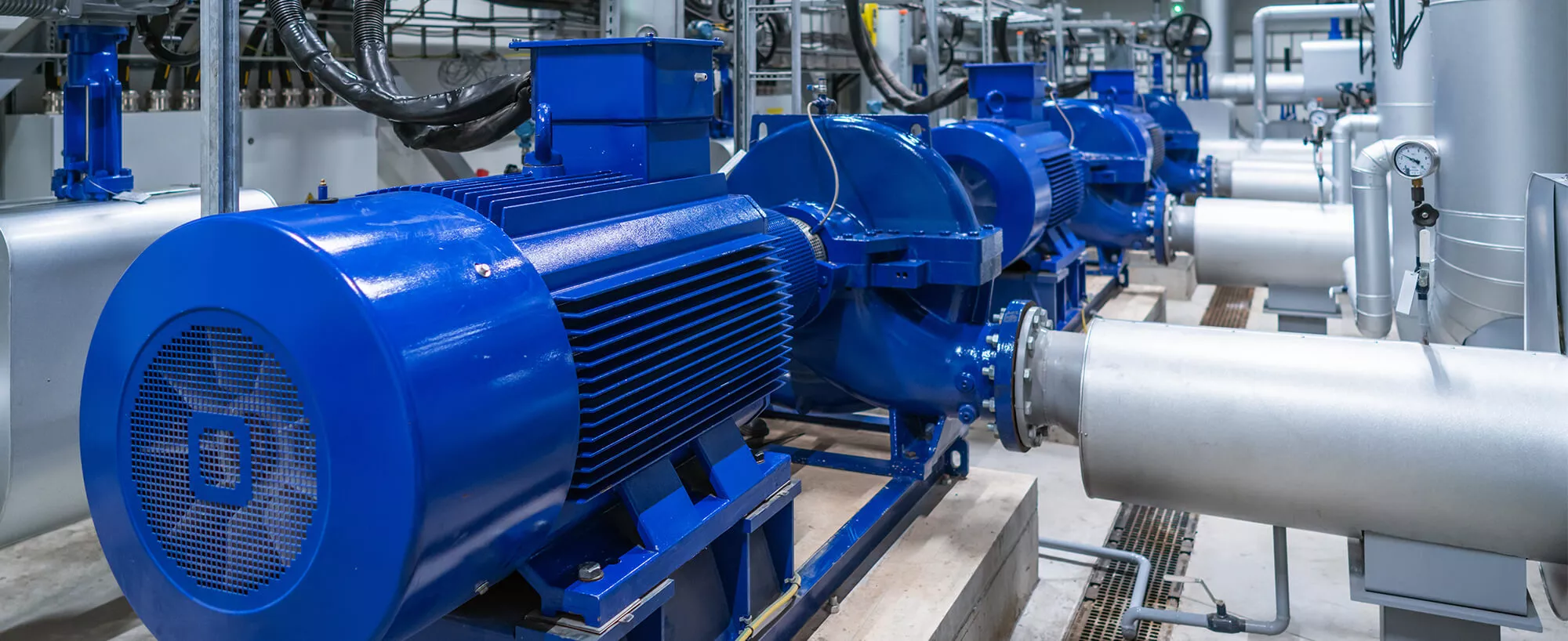

Main Areas of Use

- Pumps

- Fans

- Compressors

- Generator and Turbine Drives

- Axial and Radial Blowers

- Paper and Printing Machines

- Mixers and Stirrers

- Extruders

- Lifting and Traversing Gears

- Marine Drives

- Water Screw Drives

Technical Information

- Without further specifications, we deliver as standard: Bore tolerance H7; Keyway acc. to DIN 6885-1; Keyway width tolerance P9; Set screw per hub.

- From a peripheral speed of 30 m/s, separate balancing of the individual coupling parts is recommended.

- Without further instructions on balancing, the coupling parts are balanced individually according to DIN 21940-11 in quality G 6,3 at 1,500 1/min. The hubs are balanced half key (before grooving), the spacer without screwed-on disc packs.

- Screwing of disc packs via hexagon socket screws (coupling size 47-141), hexagon head screws (coupling size 169-254) or hexagon head screws with special nut (coupling size 262-316).

Moreover, please observe the detailed selection and operating criteria in the documents Product Paper Steel Disc Couplings RINGFEDER® TND and Tech Paper Steel Disc Couplings RINGFEDER® TND HDH.

High-Quality Disc Packs

The characteristic and functional key element of the powerful steel disc couplings of the RINGFEDER® TND series are disc packs developed on the basis of in-depth FEM analysis. They consist of multiple circular, torsionally flexible single discs made of stainless spring steel which are connected by means of high-precision sleeves to form a compact unit. High-strength screws alternately connect the disc packs, if necessary via mounted spacers, to the coupling hubs, so that the required torque is transmitted reliably, precisely and safely by the steel discs which are loaded by tension and compression. At the same time, this ensures the desired compensation capability for angular, axial and, depending on the coupling type, also radial shaft misalignments at minimum restoring forces.

Technical Data & CAD Models

| CAD |

Größe/Size

|

TKN HD

Nm |

TKN HT

Nm |

nmax

1/min |

dpre

mm |

d1kmax

mm |

d2kmax

mm |

C1

mm |

C2

mm |

E

mm |

H3

mm |

D1 mm |

D2

mm |

L2

mm |

L

mm |

SD

mm |

nSc

Stück |

Gwsb

kg |

Jsb

10-3kgm2 |

CTdynHD

106Nm/rad |

CTdynHT

106Nm/rad |

ΔKaHD

mm |

ΔKaHT

mm |

ΔKwHD

° |

ΔKwHT

° |

ΔKrHD

mm |

ΔKrHT

mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 47 | 170 | 230 | 12200 | 10 | 32 | 32 | 39,5 | 39,5 | 60 | 7,5 | 70,5 | 47 | 5 | 139 | 24 | 6 | 1,7 | 0,76 | 0,071 | 0,075 | 1,0 | 0,6 | 2 | 1,4 | 0,8 | 0,6 | |

| 47 | 170 | 230 | 12200 | 10 | 32 | 32 | 39,5 | 39,5 | 100 | 7,5 | 70,5 | 47 | 5 | 179 | 24 | 6 | 1,8 | 0,76 | 0,059 | 0,062 | 1,0 | 0,6 | 2 | 1,4 | 1,5 | 1,1 | |

| 47 | 170 | 230 | 12200 | 10 | 32 | 32 | 39,5 | 39,5 | 140 | 7,5 | 70,5 | 47 | 5 | 219 | 24 | 6 | 1,9 | 0,76 | 0,071 | 0,075 | 1,0 | 0,6 | 2 | 1,4 | 2,2 | 1,5 | |

| 63 | 320 | 420 | 9900 | 14 | 42 | 42 | 45 | 45 | 70 | 9 | 88 | 62,5 | 8 | 160 | 32 | 6 | 3,3 | 2,5 | 0,126 | 0,139 | 1,0 | 0,8 | 2 | 1,4 | 1 | 0,7 | |

| 63 | 320 | 420 | 9900 | 14 | 42 | 42 | 45 | 45 | 140 | 9 | 88 | 62,5 | 8 | 230 | 32 | 6 | 3,7 | 2,8 | 0,105 | 0,114 | 1,0 | 0,8 | 2 | 1,4 | 2,1 | 1,6 | |

| 63 | 320 | 420 | 9900 | 14 | 42 | 42 | 45 | 45 | 80 | 9 | 88 | 62,5 | 8 | 170 | 32 | 6 | 3,3 | 2,6 | 0,123 | 0,134 | 1,0 | 0,8 | 2 | 1,4 | 1,1 | 0,8 | |

| 63 | 320 | 420 | 9900 | 14 | 42 | 42 | 45 | 45 | 100 | 9 | 88 | 62,5 | 8 | 190 | 32 | 6 | 3,5 | 2,7 | 0,116 | 0,127 | 1,0 | 0,8 | 2 | 1,4 | 1,5 | 1,1 | |

| 82 | 750 | 1050 | 7500 | 15 | 55 | 55 | 55 | 55 | 180 | 10,5 | 116 | 82 | 10 | 290 | 40 | 6 | 7,7 | 9,9 | 0,226 | 0,251 | 1,4 | 0,8 | 2 | 1,4 | 2,8 | 2,1 | |

| 82 | 750 | 1050 | 7500 | 15 | 55 | 55 | 55 | 55 | 100 | 10,5 | 116 | 82 | 10 | 210 | 40 | 6 | 7,1 | 9,1 | 0,271 | 0,308 | 1,4 | 0,8 | 2 | 1,4 | 1,4 | 1,1 | |

| 82 | 750 | 1050 | 7500 | 15 | 55 | 55 | 55 | 55 | 140 | 10,5 | 116 | 82 | 10 | 250 | 40 | 6 | 7,4 | 9,5 | 0,246 | 0,277 | 1,4 | 0,8 | 2 | 1,4 | 2,1 | 1,5 | |

| 98 | 1350 | 1750 | 6200 | 19 | 65 | 65 | 60 | 60 | 100 | 12 | 140,5 | 98 | 11 | 220 | 47 | 6 | 11,1 | 21 | 0,513 | 0,543 | 2,0 | 1,2 | 2 | 1,4 | 1,5 | 1 | |

| 98 | 1350 | 1750 | 6200 | 19 | 65 | 65 | 60 | 60 | 180 | 12 | 140,5 | 98 | 11 | 300 | 47 | 6 | 12 | 23 | 0,433 | 0,454 | 2,0 | 1,2 | 2 | 1,4 | 2,8 | 2 | |

| 98 | 1350 | 1750 | 6200 | 19 | 65 | 65 | 60 | 60 | 140 | 12 | 140,5 | 98 | 11 | 260 | 47 | 6 | 11,5 | 22 | 0,469 | 0,494 | 2,0 | 1,2 | 2 | 1,4 | 2,1 | 1,5 | |

| 118 | 2400 | 3000 | 5250 | 25 | 85 | 85 | 75 | 75 | 100 | 13 | 166,5 | 118 | 12 | 250 | 55 | 6 | 18,9 | 52 | 0,914 | 0,948 | 2,4 | 1,6 | 2 | 1,4 | 1,4 | 1 | |

| 118 | 2400 | 3000 | 5250 | 25 | 85 | 85 | 75 | 75 | 140 | 13 | 166,5 | 118 | 12 | 290 | 55 | 6 | 19,6 | 54 | 0,855 | 0,884 | 2,4 | 1,6 | 2 | 1,4 | 2,1 | 1,5 | |

| 118 | 2400 | 3000 | 5250 | 25 | 85 | 85 | 75 | 75 | 180 | 13 | 166,5 | 118 | 12 | 330 | 55 | 6 | 20,3 | 56 | 0,803 | 0,829 | 2,4 | 1,6 | 2 | 1,4 | 2,8 | 2 | |

| 141 | 4000 | 5200 | 4400 | 30 | 95 | 95 | 90 | 90 | 140 | 15 | 198,5 | 141 | 14 | 320 | 64 | 6 | 31,7 | 120 | 1,306 | 1,362 | 2,8 | 1,6 | 2 | 1,4 | 2 | 1,5 | |

| 141 | 4000 | 5200 | 4400 | 30 | 95 | 95 | 90 | 90 | 180 | 15 | 198,5 | 141 | 14 | 360 | 64 | 6 | 32,5 | 130 | 1,229 | 1,279 | 2,8 | 1,6 | 2 | 1,4 | 2,7 | 2 | |

| 169 | 6500 | 8500 | 3650 | 39 | 115 | 115 | 125 | 125 | 140 | 21 | 238 | 169 | 16 | 390 | 81 | 6 | 60,2 | 340 | 2,467 | 3,035 | 3 | 2,4 | 2 | 1,4 | 2 | 1,4 | |

| 169 | 6500 | 8500 | 3650 | 39 | 115 | 115 | 125 | 125 | 180 | 21 | 238 | 169 | 16 | 430 | 81 | 6 | 61,8 | 350 | 2,375 | 2,898 | 3 | 2,4 | 2 | 1,4 | 2,6 | 1,9 | |

| 169 | 6500 | 8500 | 3650 | 39 | 115 | 115 | 125 | 125 | 250 | 21 | 238 | 169 | 16 | 500 | 81 | 6 | 64,5 | 360 | 2,231 | 2,686 | 3 | 2,4 | 2 | 1,4 | 3,8 | 2,7 | |

| 205 | 21000 | 26000 | 2950 | 59 | 140 | 140 | 160 | 160 | 200 | 28 | 295 | 205 | 22 | 520 | 112 | 8 | 119,6 | 1070 | 8,995 | 9,142 | 2,2 | 1,2 | 1 | 0,8 | 1,4 | 1,2 | |

| 205 | 21000 | 26000 | 2950 | 59 | 140 | 140 | 160 | 160 | 250 | 28 | 295 | 205 | 22 | 570 | 112 | 8 | 122,4 | 1100 | 8,265 | 8,389 | 2,2 | 1,2 | 1 | 0,8 | 1,8 | 1,5 | |

| 254 | 36000 | 44000 | 2500 | 79 | 175 | 175 | 200 | 200 | 224 | 32,2 | 345 | 254 | 26 | 624 | 133 | 8 | 207,5 | 2620 | 14,975 | 15,19 | 2,2 | 1,6 | 1 | 0,8 | 1,6 | 1,3 | |

| 254 | 36000 | 44000 | 2500 | 79 | 175 | 175 | 200 | 200 | 250 | 32,5 | 345 | 254 | 26 | 650 | 133 | 8 | 209,5 | 2640 | 14,302 | 14,497 | 2,2 | 1,6 | 1 | 0,8 | 1,8 | 1,5 | |

| 254 | 36000 | 44000 | 2500 | 79 | 175 | 175 | 200 | 200 | 300 | 32,5 | 345 | 254 | 26 | 700 | 133 | 8 | 213,3 | 2680 | 13,163 | 13,328 | 2,2 | 1,6 | 1 | 0,8 | 2,2 | 1,8 | |

| 262 | 74000 | 2050 | 90 | 180 | 180 | 210 | 210 | 280 | 34 | 420 | 262 | 32 | 700 | 137 | 8 | 261,9 | 5350 | 18,116 | 3,2 | 1 | 2,5 | ||||||

| 316 | 130000 | 1700 | 100 | 215 | 215 | 240 | 240 | 350 | 47 | 510 | 316 | 38 | 830 | 172 | 8 | 450,1 | 14430 | 36,134 | 3,8 | 1 | 3 |

| CAD |

Größe/Size |

TKN HD ft-lbs |

TKN HT ft-lbs |

nmax rpm |

dpre inch |

d1kmax inch |

d2kmax inch |

C1 inch |

C2 inch |

E inch |

H3 inch |

D1 inch |

D2 inch |

L2 inch |

L inch |

SD inch |

nSc pcs. |

Gwsb lbs |

Jsb lbs-in2 |

CTdynHD 106ft-lbs/rad |

CTdynHT 106ft-lbs/rad |

ΔKaHD inch |

ΔKaHT inch |

ΔKwHD ° |

ΔKwHT ° |

ΔKrHD inch |

ΔKrHT inch |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 47 | 125.387 | 169.641 | 12200 | 0.394 | 1.260 | 1.260 | 1.555 | 1.555 | 2.360 | 0.300 | 2.780 | 1.850 | 0.197 | 5.472 | 0.945 | 6 | 3.748 | 2.597 | 0.052 | 0.055 | 0.039 | 0.024 | 0.079 | 0.055 | 0.031 | 0.024 | |

| 47 | 125.387 | 169.641 | 12200 | 0.394 | 1.260 | 1.260 | 1.555 | 1.555 | 3.937 | 0.295 | 2.776 | 1.850 | 0.197 | 7.047 | 0.945 | 6 | 3.968 | 2.597 | 0.044 | 0.046 | 0.039 | 0.024 | 0.079 | 0.055 | 0.059 | 0.043 | |

| 47 | 125.387 | 169.641 | 12200 | 0.394 | 1.260 | 1.260 | 1.555 | 1.555 | 5.512 | 0.295 | 2.776 | 1.850 | 0.197 | 8.622 | 0.945 | 6 | 4.189 | 2.597 | 0.052 | 0.055 | 0.039 | 0.024 | 0.079 | 0.055 | 0.087 | 0.059 | |

| 63 | 236.022 | 309.779 | 9900 | 0.551 | 1.654 | 1.654 | 1.772 | 1.772 | 2.760 | 0.354 | 3.460 | 2.461 | 0.315 | 6.299 | 1.260 | 6 | 7.275 | 8.543 | 0.093 | 0.103 | 0.039 | 0.031 | 0.079 | 0.055 | 0.039 | 0.028 | |

| 63 | 236.022 | 309.779 | 9900 | 0.551 | 1.654 | 1.654 | 1.772 | 1.772 | 5.512 | 0.354 | 3.465 | 2.461 | 0.315 | 9.055 | 1.260 | 6 | 8.157 | 9.568 | 0.077 | 0.084 | 0.039 | 0.031 | 0.079 | 0.055 | 0.083 | 0.063 | |

| 63 | 236.022 | 309.779 | 9900 | 0.551 | 1.654 | 1.654 | 1.772 | 1.772 | 3.150 | 0.354 | 3.465 | 2.461 | 0.315 | 6.693 | 1.260 | 6 | 7.275 | 8.884 | 0.091 | 0.099 | 0.039 | 0.031 | 0.079 | 0.055 | 0.043 | 0.031 | |

| 63 | 236.022 | 309.779 | 9900 | 0.551 | 1.654 | 1.654 | 1.772 | 1.772 | 3.937 | 0.354 | 3.465 | 2.461 | 0.315 | 7.480 | 1.260 | 6 | 7.716 | 9.226 | 0.086 | 0.094 | 0.039 | 0.031 | 0.079 | 0.055 | 0.059 | 0.043 | |

| 82 | 553.178 | 774.449 | 7500 | 0.591 | 2.165 | 2.165 | 2.165 | 2.165 | 7.087 | 0.413 | 4.567 | 3.228 | 0.394 | 11.417 | 1.575 | 6 | 16.976 | 33.828 | 0.167 | 0.185 | 0.055 | 0.031 | 0.079 | 0.055 | 0.110 | 0.083 | |

| 82 | 553.178 | 774.449 | 7500 | 0.591 | 2.165 | 2.165 | 2.165 | 2.165 | 3.940 | 0.413 | 4.567 | 3.228 | 0.394 | 8.268 | 1.575 | 6 | 15.653 | 31.095 | 0.200 | 0.227 | 0.055 | 0.031 | 0.079 | 0.055 | 0.055 | 0.043 | |

| 82 | 553.178 | 774.449 | 7500 | 0.591 | 2.165 | 2.165 | 2.165 | 2.165 | 5.512 | 0.413 | 4.567 | 3.228 | 0.394 | 9.843 | 1.575 | 6 | 16.314 | 32.462 | 0.181 | 0.204 | 0.055 | 0.031 | 0.079 | 0.055 | 0.083 | 0.059 | |

| 98 | 995.720 | 1290.748 | 6200 | 0.748 | 2.559 | 2.559 | 2.362 | 2.362 | 3.940 | 0.470 | 5.530 | 3.858 | 0.433 | 8.661 | 1.850 | 6 | 24.471 | 71.757 | 0.378 | 0.401 | 0.079 | 0.047 | 0.079 | 0.055 | 0.059 | 0.039 | |

| 98 | 995.720 | 1290.748 | 6200 | 0.748 | 2.559 | 2.559 | 2.362 | 2.362 | 7.087 | 0.472 | 5.531 | 3.858 | 0.433 | 11.811 | 1.850 | 6 | 26.455 | 78.591 | 0.319 | 0.335 | 0.079 | 0.047 | 0.079 | 0.055 | 0.110 | 0.079 | |

| 98 | 995.720 | 1290.748 | 6200 | 0.748 | 2.559 | 2.559 | 2.362 | 2.362 | 5.512 | 0.472 | 5.531 | 3.858 | 0.433 | 10.236 | 1.850 | 6 | 25.353 | 75.174 | 0.346 | 0.364 | 0.079 | 0.047 | 0.079 | 0.055 | 0.083 | 0.059 | |

| 118 | 1770.168 | 2212.710 | 5250 | 0.984 | 3.346 | 3.346 | 2.953 | 2.953 | 3.940 | 0.510 | 6.560 | 4.646 | 0.472 | 9.843 | 2.165 | 6 | 41.667 | 177.684 | 0.674 | 0.699 | 0.094 | 0.063 | 0.079 | 0.055 | 0.055 | 0.039 | |

| 118 | 1770.168 | 2212.710 | 5250 | 0.984 | 3.346 | 3.346 | 2.953 | 2.953 | 5.512 | 0.512 | 6.555 | 4.646 | 0.472 | 11.417 | 2.165 | 6 | 43.211 | 184.518 | 0.631 | 0.652 | 0.094 | 0.063 | 0.079 | 0.055 | 0.083 | 0.059 | |

| 118 | 1770.168 | 2212.710 | 5250 | 0.984 | 3.346 | 3.346 | 2.953 | 2.953 | 7.087 | 0.512 | 6.555 | 4.646 | 0.472 | 12.992 | 2.165 | 6 | 44.754 | 191.352 | 0.592 | 0.611 | 0.094 | 0.063 | 0.079 | 0.055 | 0.110 | 0.079 | |

| 141 | 2950.280 | 3835.364 | 4400 | 1.181 | 3.740 | 3.740 | 3.543 | 3.543 | 5.510 | 0.590 | 7.810 | 5.551 | 0.551 | 12.598 | 2.520 | 6 | 69.887 | 410.040 | 0.963 | 1.005 | 0.110 | 0.063 | 0.079 | 0.055 | 0.079 | 0.059 | |

| 141 | 2950.280 | 3835.364 | 4400 | 1.181 | 3.740 | 3.740 | 3.543 | 3.543 | 7.087 | 0.591 | 7.815 | 5.551 | 0.551 | 14.173 | 2.520 | 6 | 71.650 | 444.210 | 0.907 | 0.943 | 0.110 | 0.063 | 0.079 | 0.055 | 0.106 | 0.079 | |

| 169 | 4794.205 | 6269.345 | 3650 | 1.535 | 4.528 | 4.528 | 4.921 | 4.921 | 5.512 | 0.827 | 9.370 | 6.654 | 0.630 | 15.354 | 3.189 | 6 | 132.718 | 1161.780 | 1.820 | 2.239 | 0.118 | 0.094 | 0.079 | 0.055 | 0.079 | 0.055 | |

| 169 | 4794.205 | 6269.345 | 3650 | 1.535 | 4.528 | 4.528 | 4.921 | 4.921 | 7.087 | 0.827 | 9.370 | 6.654 | 0.630 | 16.929 | 3.189 | 6 | 136.246 | 1195.950 | 1.752 | 2.138 | 0.118 | 0.094 | 0.079 | 0.055 | 0.102 | 0.075 | |

| 169 | 4794.205 | 6269.345 | 3650 | 1.535 | 4.528 | 4.528 | 4.921 | 4.921 | 9.843 | 0.827 | 9.370 | 6.654 | 0.630 | 19.685 | 3.189 | 6 | 142.198 | 1230.120 | 1.646 | 1.981 | 0.118 | 0.094 | 0.079 | 0.055 | 0.150 | 0.106 | |

| 205 | 15488.970 | 19176.820 | 2950 | 2.323 | 5.512 | 5.512 | 6.299 | 6.299 | 7.900 | 1.100 | 11.600 | 8.071 | 0.866 | 20.472 | 4.409 | 8 | 263.673 | 3656.190 | 6.635 | 6.743 | 0.087 | 0.047 | 0.039 | 0.031 | 0.055 | 0.047 | |

| 205 | 15488.970 | 19176.820 | 2950 | 2.323 | 5.512 | 5.512 | 6.299 | 6.299 | 9.843 | 1.102 | 11.614 | 8.071 | 0.866 | 22.441 | 4.409 | 8 | 269.846 | 3758.700 | 6.097 | 6.188 | 0.087 | 0.047 | 0.039 | 0.031 | 0.071 | 0.059 | |

| 254 | 26552.520 | 32453.080 | 2500 | 3.110 | 6.890 | 6.890 | 7.874 | 7.874 | 8.800 | 1.300 | 13.600 | 10.000 | 1.024 | 24.567 | 5.236 | 8 | 457.460 | 8952.540 | 11.046 | 11.205 | 0.087 | 0.063 | 0.039 | 0.031 | 0.063 | 0.051 | |

| 254 | 26552.520 | 32453.080 | 2500 | 3.110 | 6.890 | 6.890 | 7.874 | 7.874 | 9.843 | 1.280 | 13.583 | 10.000 | 1.024 | 25.591 | 5.236 | 8 | 461.869 | 9020.880 | 10.550 | 10.693 | 0.087 | 0.063 | 0.039 | 0.031 | 0.071 | 0.059 | |

| 254 | 26552.520 | 32453.080 | 2500 | 3.110 | 6.890 | 6.890 | 7.874 | 7.874 | 11.811 | 1.280 | 13.583 | 10.000 | 1.024 | 27.559 | 5.236 | 8 | 470.246 | 9157.560 | 9.709 | 9.831 | 0.087 | 0.063 | 0.039 | 0.031 | 0.087 | 0.071 | |

| 262 | 54580.180 | 2050 | 3.543 | 7.087 | 7.087 | 8.268 | 8.268 | 11.024 | 1.339 | 16.535 | 10.315 | 1.260 | 27.559 | 5.394 | 8 | 577.391 | 18280.950 | 13.363 | 0.126 | 0.039 | 0.098 | ||||||

| 316 | 95884.100 | 1700 | 3.937 | 8.465 | 8.465 | 9.449 | 9.449 | 13.780 | 1.850 | 20.079 | 12.441 | 1.496 | 32.677 | 6.772 | 8 | 992.301 | 49307.310 | 26.654 | 0.150 | 0.039 | 0.118 |

360° Product View

Tap and rotate the XR Model below and experience RINGFEDER® TND HDH in an interactive, touch-enabled 360° Product View. To access full-screen mode on your laptop or desktop device, simply double-click on the product.

Images & Drawings

Smart Modular System

Thanks to the unitized design of the RINGFEDER® TND series and the accompanying highly flexible modular system, consisting of several disc pack and hub types, mounting options as well as spacer variants and lengths, there is always one coupling version available that is optimally suited for your individual application. Furthermore, customized special solutions can also be realized at short delivery times in specific case of need. For example, in addition to other hub combinations and the replacement of hubs by connecting flanges, functional supplements like brake disks or drums as well as anti-flail devices are also possible.

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.