Industrial Buffers

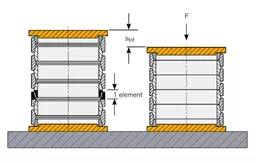

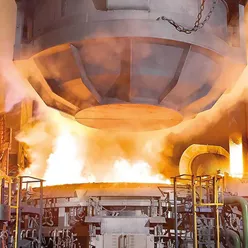

In addition to sole spring columns, our high-performance RINGFEDER® Friction Springs are also available as complete, application- and customer-specific buffer versions in various shapes and sizes for diverse use cases, e.g. in mechanical engineering, in raw material extraction and processing, or in the aviation and aerospace industry. Common designs include push-pull units as highly effective vibration dampers or absorbers, and slipping clutches for reliable protection against overloads.

Product Characteristics

Your Benefits

RINGFEDER® Friction Springs have a number of superior advantages compared to conventional damping solutions:

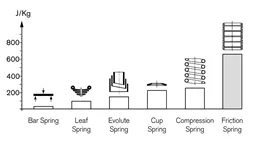

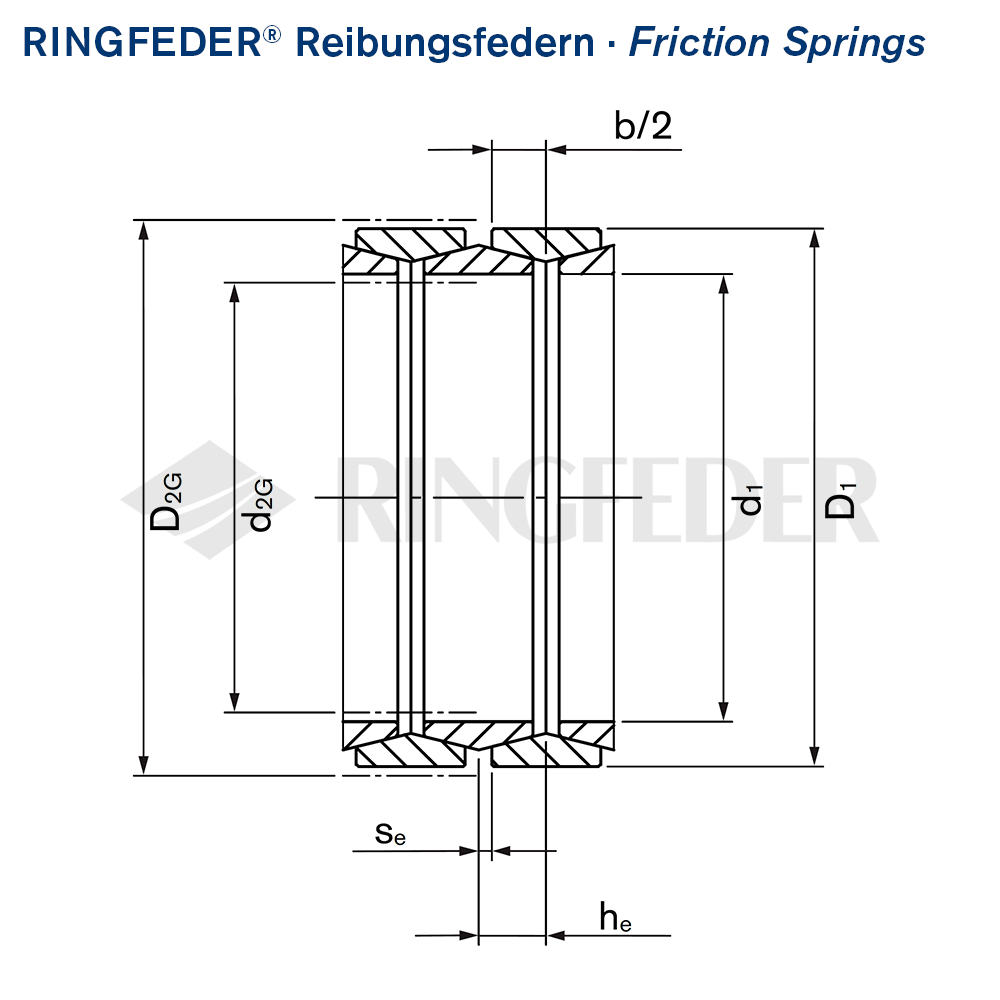

- High spring work at low weight and volume – As RINGFEDER® Friction Springs make full use of the spring material, dimensions and weight are reduced to a minimum. The decisive factor here is the spring work.

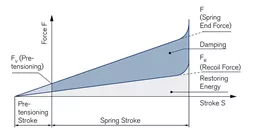

- High damping capability – The damping of the RINGFEDER® Friction Springs is 66% as standard, which means that the energy introduced is quickly absorbed and resonance effects are suppressed completely. Variations in damping between 33% and 66% are possible by using other lubricants specific to the customer and application.

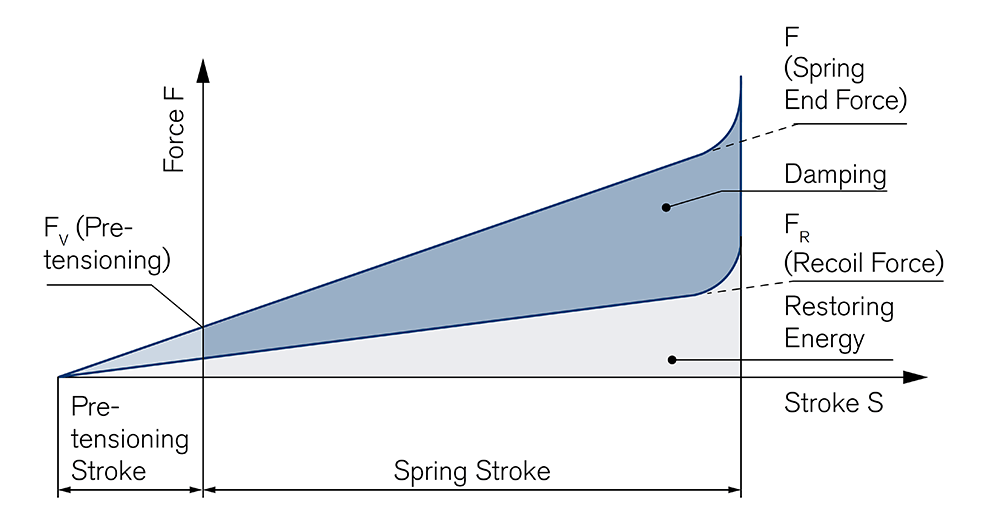

- Spring work and damping effect independent from load speed – The force-stroke diagram of the RINGFEDER® Friction Springs applies for all operating conditions. In contrast to other damping systems, RINGFEDER® Friction Springs provide full spring work and damping effect even when the load is applied extremely slowly or quickly.

- Overload-safe in block position – RINGFEDER® Friction Springs are generally designed to "block", so it is therefore ensured that the admissible stresses cannot be exceeded and the RINGFEDER® Friction Springs will not be damaged.

- Temperature-independence – In hydraulic dampers or synthetic springs, the force-stroke diagram is influenced by temperature fluctuations and inherent heating. The characteristic curve of RINGFEDER® Friction Springs is constant in the temperature range -20 °C to +60 °C. The self-heating of the spring due to damping must be taken into account. For applications outside the temperature range mentioned, please contact our experts.

- Maintenance-free – Generally, relubrication of the operating RINGFEDER® Friction Spring is not required. Use of other lubricants may even lead to spring failure.

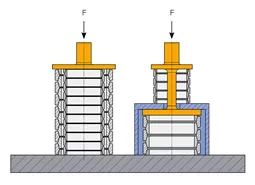

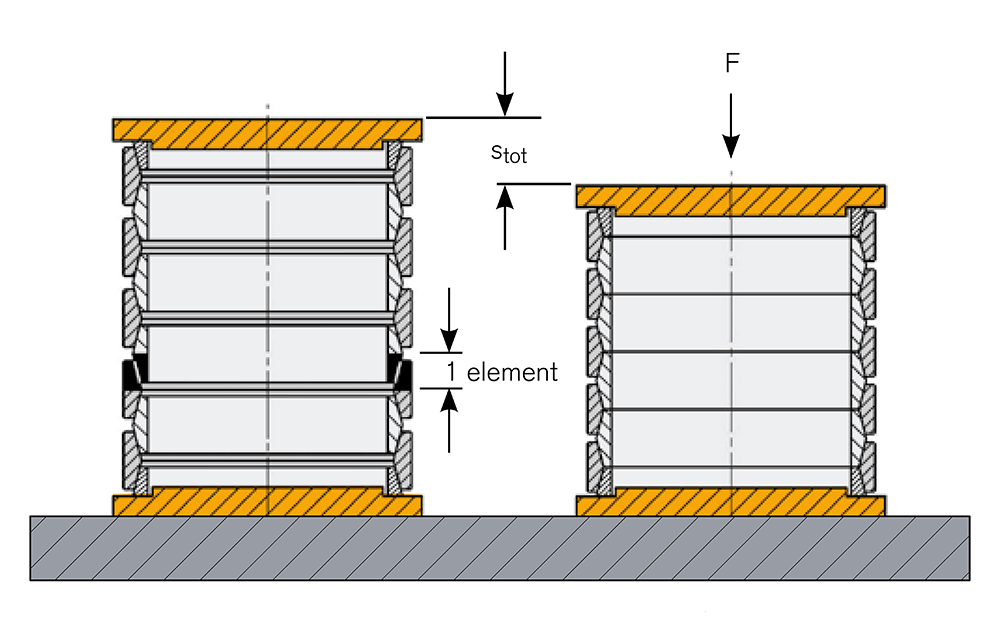

- Parallel and serial arrangement of springs – In order to utilize an existing installation space even better, RINGFEDER® Friction Springs offer the additional option of arranging the spring columns in two different manners: Parallel arrangement for higher forces, serial arrangement for more spring travel.

- Individual designs for specific use cases – In addition to the standard RINGFEDER® Friction Springs, we are more than happy to offer you a solution tailored to your individual application.

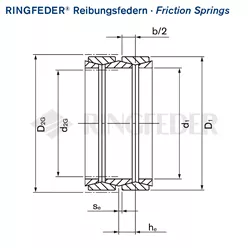

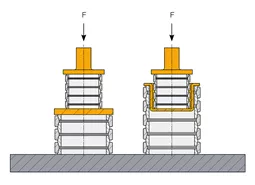

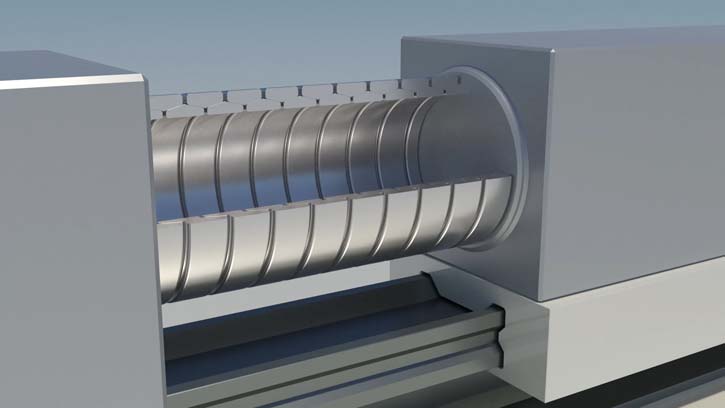

Structure of a Friction Spring

If a RINGFEDER® Friction Spring consisting of e elements concludes with half rings, its unstressed length is:

- Lo = e · he

The total spring travel can be calculated using the following equation:

- s = e · se

Without taking into account the pretensioning force, the spring work is:

- W = e · We

The end force does not change with the number of elements.

Selection and Installation Notes

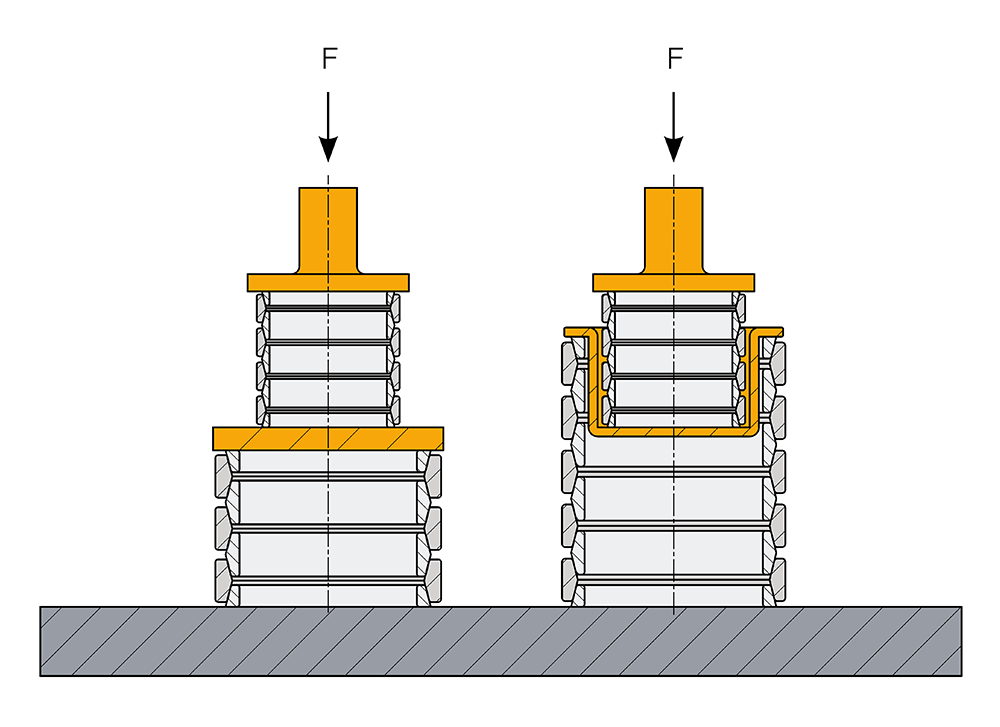

- Pretensioning – RINGFEDER® Friction Springs have to be pretensioned with min. of 5%, preferably 10% of the total spring travel. In order not to impair the lubricant film, the pretensioning force should not exceed 50 %. Exceptions are possible after consultation.

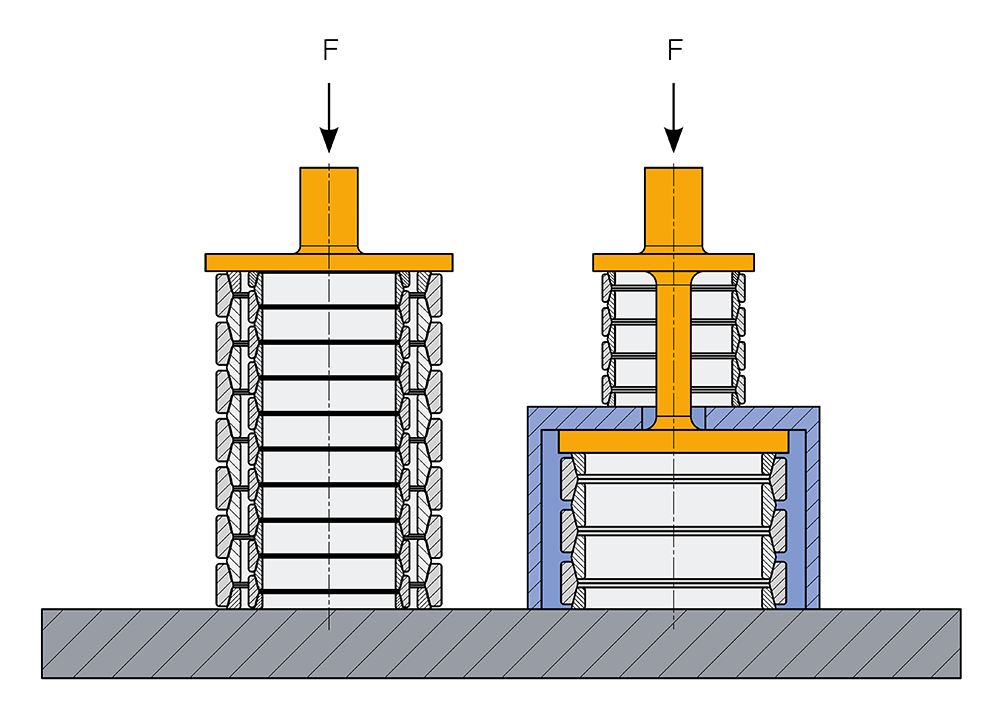

- Guiding – For RINGFEDER® Friction Springs, a guiding must be provided either at the inner or outer diameter. Exceptions apply to short springs whose length is ≤ 1.5 D1, provided they are loaded between parallel guided compression plates.

- Lubrication – Only the special lubricants recommended by us must be used for lubrication, as the conical surfaces are under enormous contact pressure. In general, the quantity of grease provided with the spring is sufficient. Relubrication is not required.

- Observe the diagram – In the case of buffer springs, the absorbable spring work in J, i.e. the area under the load curve, is of interest. If, on the other hand, the spring is to apply a contact force, the recoil curve applies. The latter can be raised if friction-minimizing lubricants are used. Here we ask for your specifications.

- Sealing – RINGFEDER® Friction Springs must be installed protected against dirt and moisture so as not to impair the lubricant film. Simple sliding guides are sufficient. In case of heavy dirt and/or moisture development, folding bellows are recommended.

Images & Drawings

Technical Data & CAD Models

You require CAD data for this product? Of course, we are more than happy to provide you with these. Contact us quickly and easily via our request form, by e-mail or using the "Need Help?" feature at the bottom right of this site.

| CAD |

Größe/Size

|

Typ

|

Fv

kN |

F

kN |

s

mm |

W

J |

L

mm |

D

mm |

DB

mm |

Gw

kg |

b

mm |

db

mm |

Bemerkung

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 06300 | 6 | 54 | 27 | 820 | 202 | 112 | 150 | 10 | 100 | 18 | ||

| 2 | 06300 | 6 | 54 | 37 | 1100 | 262 | 112 | 150 | 12 | 100 | 18 | ||

| 3 | 06300 | 6 | 54 | 55 | 1640 | 374 | 112 | 150 | 17 | 100 | 18 | ||

| 4 | 06300 | 6 | 54 | 64 | 1900 | 434 | 112 | 150 | 19 | 100 | 18 | ||

| 5 | 06300 | 6 | 54 | 74 | 2200 | 494 | 112 | 150 | 20 | 100 | 18 | ||

| 6 | 08000 | 7 | 83 | 33 | 1500 | 230 | 122 | 200 | 13 | 110 | 18 | ||

| 7 | 08000 | 7 | 83 | 46 | 2050 | 306 | 122 | 200 | 16 | 110 | 18 | ||

| 8 | 08000 | 7 | 83 | 66 | 2950 | 428 | 122 | 200 | 23 | 110 | 18 | ||

| 9 | 08000 | 7 | 83 | 79 | 3550 | 505 | 122 | 200 | 26 | 110 | 18 | ||

| 10 | 08000 | 7 | 83 | 92 | 4150 | 582 | 122 | 200 | 28 | 110 | 18 | ||

| 11 | 10000 | 10 | 125 | 45 | 3000 | 300 | 142 | 250 | 22 | 130 | 23 | ||

| 12 | 10000 | 10 | 125 | 61 | 4100 | 397 | 142 | 250 | 26 | 130 | 23 | ||

| 13 | 10000 | 10 | 125 | 89 | 6000 | 571 | 142 | 250 | 37 | 130 | 23 | ||

| 14 | 10000 | 10 | 125 | 105 | 7050 | 667 | 142 | 250 | 42 | 130 | 23 | ||

| 15 | 10000 | 10 | 125 | 121 | 8150 | 763 | 142 | 250 | 45 | 130 | 23 | ||

| 16 | 12400 | 20 | 200 | 51 | 5600 | 366 | 178 | 250 | 39 | 155 | 23 | ||

| 17 | 12400 | 20 | 200 | 65 | 7150 | 454 | 178 | 250 | 45 | 155 | 23 | ||

| 18 | 12400 | 20 | 200 | 102 | 11200 | 696 | 178 | 250 | 64 | 155 | 23 | ||

| 19 | 12400 | 20 | 200 | 116 | 12800 | 784 | 178 | 250 | 75 | 155 | 23 | ||

| 20 | 12400 | 20 | 200 | 130 | 14300 | 872 | 178 | 250 | 78 | 155 | 23 | ||

| 21 | 16600 | 10 | 350 | 75 | 13900 | 500 | 235 | 370 | 85 | 200 | 27 | ||

| 22 | 16600 | 10 | 350 | 95 | 17500 | 630 | 235 | 370 | 105 | 200 | 27 | ||

| 23 | 16600 | 10 | 350 | 140 | 25900 | 880 | 235 | 370 | 145 | 200 | 27 | ||

| 24 | 16600 | 10 | 350 | 165 | 30500 | 1040 | 235 | 370 | 160 | 200 | 27 | ||

| 25 | 16600 | 10 | 350 | 190 | 35000 | 1200 | 235 | 370 | 165 | 200 | 27 | ||

| 27 | 19600 | 20 | 600 | 105 | 32000 | 620 | - | 153 | - | 26 | Teller: 450x340 |

| CAD |

Größe/Size |

Typ |

Fv lbs |

F lbs |

s inch |

W ft-lbs |

L inch |

D inch |

DB inch |

Gw lbs |

b inch |

db inch |

Bemerkung |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 06300 | 1348 | 12136 | 1.063 | 605 | 7.953 | 4.409 | 5.906 | 22.05 | 3.937 | 0.709 | ||

| 2 | 06300 | 1348 | 12136 | 1.457 | 811 | 10.315 | 4.409 | 5.906 | 26.46 | 3.937 | 0.709 | ||

| 3 | 06300 | 1348 | 12136 | 2.165 | 1210 | 14.724 | 4.409 | 5.906 | 37.48 | 3.937 | 0.709 | ||

| 4 | 06300 | 1348 | 12136 | 2.520 | 1401 | 17.087 | 4.409 | 5.906 | 41.89 | 3.937 | 0.709 | ||

| 5 | 06300 | 1348 | 12136 | 2.913 | 1623 | 19.449 | 4.409 | 5.906 | 44.09 | 3.937 | 0.709 | ||

| 6 | 08000 | 1573 | 18653 | 1.299 | 1106 | 9.055 | 4.803 | 7.874 | 28.66 | 4.331 | 0.709 | ||

| 7 | 08000 | 1573 | 18653 | 1.811 | 1512 | 12.047 | 4.803 | 7.874 | 35.27 | 4.331 | 0.709 | ||

| 8 | 08000 | 1573 | 18653 | 2.598 | 2176 | 16.850 | 4.803 | 7.874 | 50.71 | 4.331 | 0.709 | ||

| 9 | 08000 | 1573 | 18653 | 3.110 | 2618 | 19.882 | 4.803 | 7.874 | 57.32 | 4.331 | 0.709 | ||

| 10 | 08000 | 1573 | 18653 | 3.622 | 3061 | 22.913 | 4.803 | 7.874 | 61.73 | 4.331 | 0.709 | ||

| 11 | 10000 | 2247 | 28092 | 1.772 | 2213 | 11.811 | 5.591 | 9.843 | 48.50 | 5.118 | 0.906 | ||

| 12 | 10000 | 2247 | 28092 | 2.402 | 3024 | 15.630 | 5.591 | 9.843 | 57.32 | 5.118 | 0.906 | ||

| 13 | 10000 | 2247 | 28092 | 3.504 | 4425 | 22.480 | 5.591 | 9.843 | 81.57 | 5.118 | 0.906 | ||

| 14 | 10000 | 2247 | 28092 | 4.134 | 5200 | 26.260 | 5.591 | 9.843 | 92.59 | 5.118 | 0.906 | ||

| 15 | 10000 | 2247 | 28092 | 4.764 | 6011 | 30.039 | 5.591 | 9.843 | 99.21 | 5.118 | 0.906 | ||

| 16 | 12400 | 4495 | 44947 | 2.008 | 4130 | 14.409 | 7.008 | 9.843 | 85.98 | 6.102 | 0.906 | ||

| 17 | 12400 | 4495 | 44947 | 2.559 | 5274 | 17.874 | 7.008 | 9.843 | 99.21 | 6.102 | 0.906 | ||

| 18 | 12400 | 4495 | 44947 | 4.016 | 8261 | 27.402 | 7.008 | 9.843 | 141.10 | 6.102 | 0.906 | ||

| 19 | 12400 | 4495 | 44947 | 4.567 | 9441 | 30.866 | 7.008 | 9.843 | 165.35 | 6.102 | 0.906 | ||

| 20 | 12400 | 4495 | 44947 | 5.118 | 10547 | 34.331 | 7.008 | 9.843 | 171.96 | 6.102 | 0.906 | ||

| 21 | 16600 | 2247 | 78658 | 2.953 | 10252 | 19.685 | 9.252 | 14.567 | 187.39 | 7.874 | 1.063 | ||

| 22 | 16600 | 2247 | 78658 | 3.740 | 12907 | 24.803 | 9.252 | 14.567 | 231.49 | 7.874 | 1.063 | ||

| 23 | 16600 | 2247 | 78658 | 5.512 | 19103 | 34.646 | 9.252 | 14.567 | 319.67 | 7.874 | 1.063 | ||

| 24 | 16600 | 2247 | 78658 | 6.496 | 22496 | 40.945 | 9.252 | 14.567 | 352.74 | 7.874 | 1.063 | ||

| 25 | 16600 | 2247 | 78658 | 7.480 | 25815 | 47.244 | 9.252 | 14.567 | 363.76 | 7.874 | 1.063 | ||

| 27 | 19600 | 4495 | 134842 | 4.134 | 23602 | 24.409 | 337.31 | 1.024 | Buffer plate: 450x340 |

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.