Minimum Space, Maximum Damping

In the demanding sector of aerospace technology, the high-performance and maintenance-free friction springs designed by RINGFEDER® do not only meet the strict safety standards, but also comply with the manufacturers’ requirements with regard to minimum space dimensioning. Their low weight and compact design with a high and reliable damping performance make them the ideal solution for users all around the world – also in terms of economic and ecological aspects. RINGFEDER® friction springs are used as important safety-relevant components for quick and precise energy absorption, for instance in the landing flaps, edge flaps and emergency exit doors of airplanes of various types and by various manufacturers.

Effective Overload Protection by Friction Springs

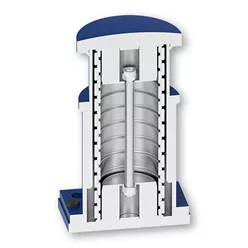

In a special application involving special challenges, a RINGFEDER® friction spring is used within a torque limiter with a ball latch. It is located in the drive line of the movable lift aids on the wing panels, in order to protect the motor and the gearbox from damage if there is a critical blocking of the flaps. The retraction force of the individually designed friction spring holds the ball in the arrester in the corresponding pockets, transmitting the torque from one side of the limiter to the other. If the torque exceeds the limit value defined, the balls emerge from their pockets and compress the spring, which may cause the torque limiter to slip through. In this way, safe and reliable overload protection is established.

High-Performance Shock Absorption Even in the Event of Turbulences

The so-called stratosphere observatory for infrared astronomy, in short, SOFIA, is a telescope developed in collaboration of NASA and the German Aerospace Center on board of a Boeing 747. In use since 2010, it has provided a whole new and unique observation platform to astronomical research. During the flight progress, the powerful reflector telescope is aligned to objects to be observed within the solar system. In order to be able to consistently keep these objects under observation during the flight, the telescope must be continuously updated. The rotating device and adjusting unit required for this purpose were provided with specially developed, maintenance-free aluminium precision buffers designed by RINGFEDER®, serving to dampen the end positions of the telescope and therefore ensuring its proper function even in the event of turbulences.

Highly Reliable Opening of Exit Doors in Case of an Emergency

For the use in the emergency exit doors of a passenger aircraft of the A321 type, the manufacturer AIRBUS confronted RINGFEDER® with the challenging task of designing a high-performance, innovative safety coupling. This coupling ensures that, in case of an emergency, the exit doors are in a defined torque range and can therefore be opened by any passenger irrespective of his/her physical constitution. For this purpose, a specially dimensioned design with an outer diameter of only 13 millimetres were used, which furthermore also complies with the strict specifications of the manufacturer with regard to corrosion and temperature resistance, closeness of the system without any adhesion or fittings, weight and maintenance friendliness.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.