Highly Specific Individual and Comprehensive System Solutions for the Most Important Building Material Worldwide

From the tapping and extraction of resources to the cooling, grinding, mixing, homogenisation and storage of the end product, including the reconditioning and processing in crushing units, vertical and raw mills and rotary kilns: in the field of cement production, tailor-made, application-oriented solutions are required which can cope with potentially huge mechanical and thermal stress. A complex, challenging field of application that is perfect for the use of the RINGFEDER® coupling and locking device systems, which are always manufactured so as to meet the highest quality standards. Because, if the precise and reliable transmission of driving forces is a vital factor along the entire value chain of the cement industry, RINGFEDER® products are the preferred choice of leading users to ensure optimum functionality and efficiency – whether in the form of individual precision work or as a proven standard version, comprehensive system solutions or highly specific individual solutions.

Constant Performance with Continuous Stress

Rock crushers are used in one of the first steps of cement production for the coarse grinding of the raw material mined as crushed material, e.g. limestone or iron ore. The throughput of large plants that are mostly in operation round the clock can be several thousand tonnes of rock per hour. Correspondingly massive is the stress in the form of bending torques, radial loads, the formation of dust and dirt, to which the locking devices utilised to connect the crusher roll and the rotor shaft are continuously subjected. RINGFEDER® supplies perfectly suitable locking assembly and shrink disc solutions, always taking into consideration the application-specific conditions with regard to the size of the plant and its capacity, the type of rock and its hardness, speeds and torques, shaft diameters as well as important environmental factors. This contributes significantly to ensuring the effective and trouble-free operation of individually different crushing facilities – since operational disorders or even failures involve huge costs and must ideally be entirely avoided.

Sustainable Reduction of Service Costs and Downtimes

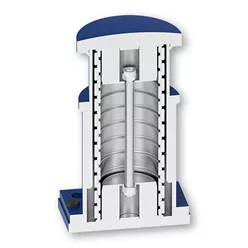

Specially for the use in a ball mill for cement production, RINGFEDER® has designed a special locking assembly solution by means of which one customer based in India could sustainably eliminate operational downtimes, which occurred at a frequent rate and which involved downtime and maintenance costs. Root cause analyses that were carried out beforehand together with the operator of the mill proved that the locking assembly manufactured by a competitor, which had been used previously to establish the shaft-pinion connection, showed a concentricity error of up to 400 µm, had broken into several pieces and could only be dismounted at a tremendous effort. The extremely user-friendly RINGFEDER® solution: a locking assembly of the proven RfN 7015.0 series, which, thanks to the proper selection of material and the manufacturing process as well as proper installation permanently reduced both the concentricity error and the vibration values to a harmless level. Due to the operational reliability ensured by this measure, the customer is now implementing the RINGFEDER® locking device successively at other mill sites throughout India.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.