Excellent Solutions for Gas Compressor Plants

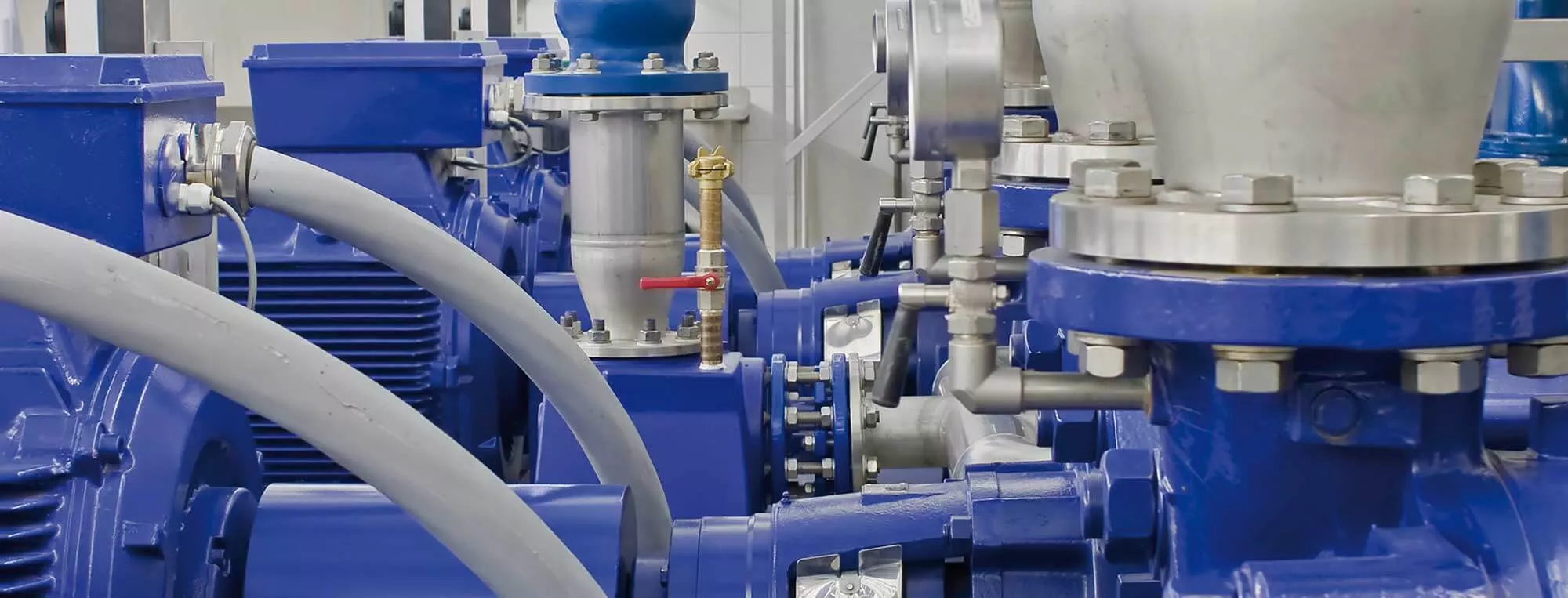

In the sector of compressor technology, RINGFEDER® coupling and locking device systems are used to establish an effective and stable connection between the motor and compressor. Because they fully meet the variety of requirements regarding the required power transmission, which in the first place must be characterised by absolute consistency and reliability – even up to maximum torque ranges. Correspondingly, the RINGFEDER® standard and special solutions designed for the respective applications substantially contribute worldwide to ensure perfect functioning and maximum durability of compressors.

Variable Coupling Concepts Meeting Maximum Standards

The technical challenges to be faced by the designers of compressors are numerous and complex: Noise and weight reduction, standardisation, compactness, energy efficiency – and all the while ensuring the best-possible and consistent functionality depending on the purpose, site and time of the application. RINGFEDER® supports the manufacturers in mastering these challenges, for example by individually designable, flexible coupling systems combining compact and elastic properties with the capacity of compensating for misalignments and furthermore – e.g. by the additional use of a brake disc – meet safety-relevant specifications.

Making Light Work of Inspection and Maintenance

Downtimes are extremely costly and labour-intensive, in particular if they occur spontaneously and unexpectedly. The effective prevention of such downtimes requires regular inspection and maintenance procedures, which have to be performed as quickly and easily as possible. Users are therefore provided with high-performance RINGFEDER® jaw couplings, e.g. from the TNM series, which come in variants with multi-piece design. This makes it possible to perform the inspection and, if necessary, the replacement, of an elastic intermediate ring or a brake disc without the axial displacement of units connected at the drive end and the output end. Service costs are therefore substantially reduced.

Versatile, Specific, Reliable

In the sector of gas compressor devices and plants, RINGFEDER® offers perfectly suited locking device and coupling systems for various applications of maximum complexity. Our top priorities are to provide the exact and task-specific dimensioning of the respective solutions and to consistently ensure reliability and maintenance-friendliness – in order to provide maximum customer benefit with regard to the functionality and durability of our products. Our versatile standard and special products always comply with the standards and regulations that are relevant in this sector, e.g. API or ATEX as well as special factory standards.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.