Reliable Performance Under Toughest Conditions

For the most diverse and complex applications in the field of construction machinery, e.g. tunnel excavation machines, hoisting gear and transport equipment, RINGFEDER® offers solutions implementing maximum power densities even under extreme conditions. Whether couplings for huge torques and speeds or locking devices and damping elements for extreme dimensions and loads have to be implemented – in larger-scale and smaller-scale plants from the construction machinery industry, RINGFEDER® products ensure maximum productivity, durability and safety.

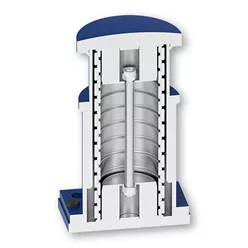

Friction Springs for the Perfect Road Surface

An optimum road surface is the fundamental prerequisite to ensure safe, comfortable and economic driving. In order to implement this, the road construction machine used must achieve a correspondingly high-quality output. In the case of asphalt pavers, RINGFEDER® supports this by the use of compact and robust friction springs, which are specially designed in collaboration with one of the world’s leading manufacturer of road construction machines: By means of friction springs, installed to ensure impact protection, an excellent image of quality is put on the road – even if ambient conditions are extremely rough as is the case with heavy pollution, high air humidity or extreme differences in temperature.

Reliable and Safe Rotor Shaft Protection

One of the main tasks of shredder facilities for instance is the recycling of road material, preferably without any faults and downtimes. Critical overload situations during operation can be caused by foreign substances, e.g. metal, which are accidentally contained. Furthermore, due to the variety of sizes and shapes of rocks, huge transverse forces act on the rotor shaft which is the key component of the shredder roll. Specially designed RINGFEDER® locking assemblies which, thanks to dimensions specially tailored to the application, effectively absorb both intermittent overloads and bending torques, protect the rotor shaft from the negative impacts of these extreme loads and in this way prevent a failure of the shredder facility.

Efficient Application Solutions for Building and Construction Machinery

Whether we’re talking about tunnel construction facilities, cranes, shredder facilities, excavator and transport vehicles or similar devices – RINGFEDER® offers the perfect efficient solution for building and construction machinery of any type, design and size. Highly elastic coupling systems for diesel units or conventional shaft couplings for hub drives are typical customer applications in this sector. Our torsionally stiff flange couplings as well as our elastic and highly elastic flange couplings, our range of locking assemblies and shrink discs as well as our friction springs are also perfectly suited for the use in this segment. Always specially tailored to meet the specific requirements of the customer and the application.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.