Durable, Reliable, Innovative

Loading, conveying, lifting, moving: The tried-and-tested RINGFEDER® coupling and locking device systems play a decisive role in ensuring reliable and trouble-free operation of hoists and cranes – whether we are talking about sea ports and airports, large transshipment facilities or logistics centres. The benefits for our users are not only the exceptional economic viability and capacity of the RINGFEDER® solutions used, but also our profound expertise and our long-standing experience as specialist and system provider in the sector of drive technology for cranes and hoists of any type, size and design.

Special Barrel Coupling Solutions for Lifting Applications

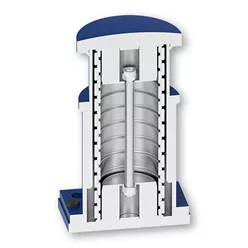

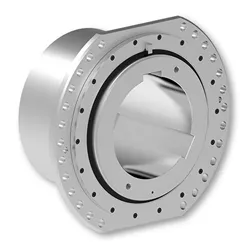

Drum couplings are typically used in cable drum drives of lifting devices, winches or storage and retrieval machines. With its TNK product series, RINGFEDER® offers a comprehensive and powerful standard program as well as customised special solutions for these applications. In the case of a special storage and retrieval unit, an extremely compact and flexible variant of a drum coupling was specially designed. The key requirements specified by the customer were a minimum installation space and the option for the adaptation to different shaft diameters. The innovative RINGFEDER® solution: A drum coupling with an installation dimension of only 160 mm including an increased torque range as well as a modular locking assembly which is provided with a constant outer diameter in the drilling range of 28 to 60 mm.

Flexibility in the Event of Maintenance and Service Work

Applications for drum couplings of any type and size are predominately implemented via positive-locking shaft-hub connections. When maintenance and service work is performed, the necessary disassembly is therefore potentially complicated by firmly installed shafts. Our extensive range of RINGFEDER® locking assemblies therefore offers alternative solutions, for example in the form of frictional, backlash-free shaft-hub connections. Depending on the requirement and customer request, RINGFEDER® furthermore implements various locking assembly solutions with consistent coupling dimensions. This enables the users to ensure the function of drives with different shaft diameters by quickly and easily replacing the locking devices.

Sophisticated Solutions for Maximum Demands

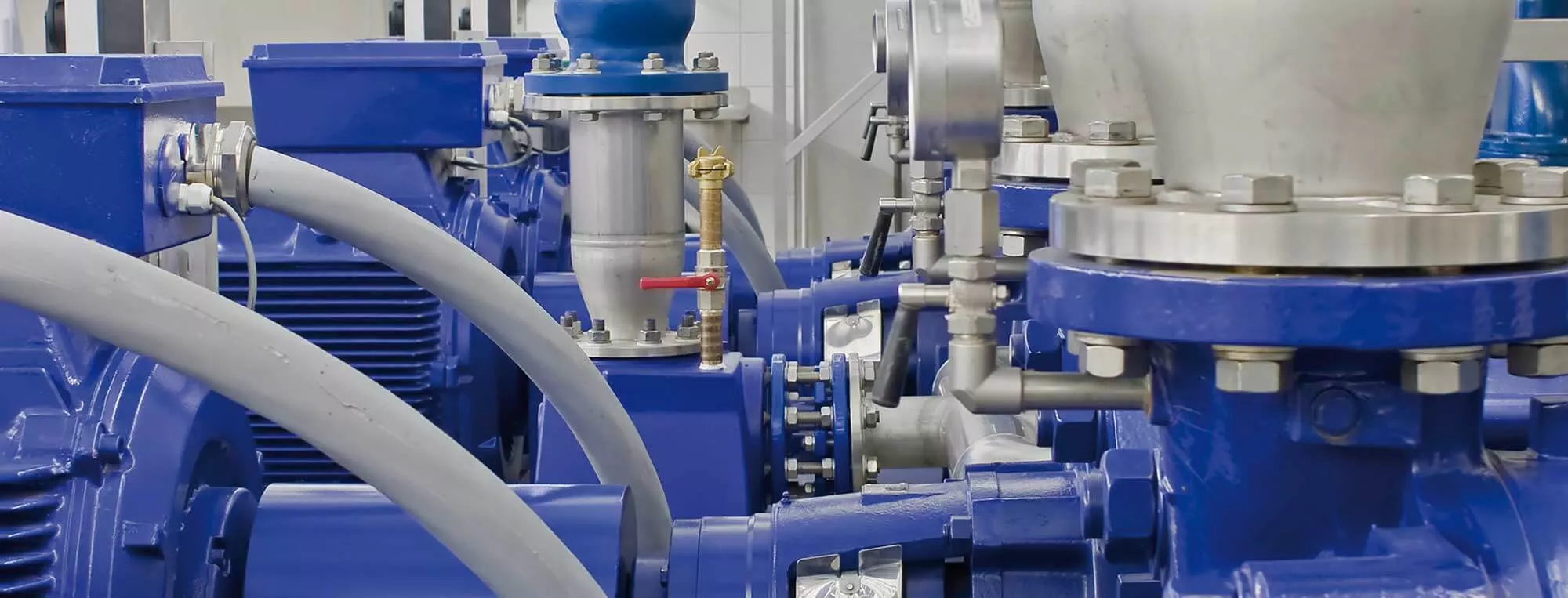

Maximum torque transmissions, extreme environmental influences and different operating times and loads are the typical framework conditions in the fields of crane and lifting technology. The requirements to be met by the drive components used to ensure reliable and low-maintenance operation and to completely rule out downtimes as far as possible are therefore tremendously high. That's why users all around the globe rely on top-quality coupling and locking device systems designed by RINGFEDER®: Durable barrel couplings for a variety of reel applications, highly elastic shaft couplings as connection elements between the drive and output, robust locking devices for fastening belt and gear wheels or shaft-mounted gearboxes – customers are always provided with perfectly suited standard and special solutions matching the requirements of their specific application.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.