First-Class Connection: Locking Device and Coupling Solutions for Gear Manufacturing

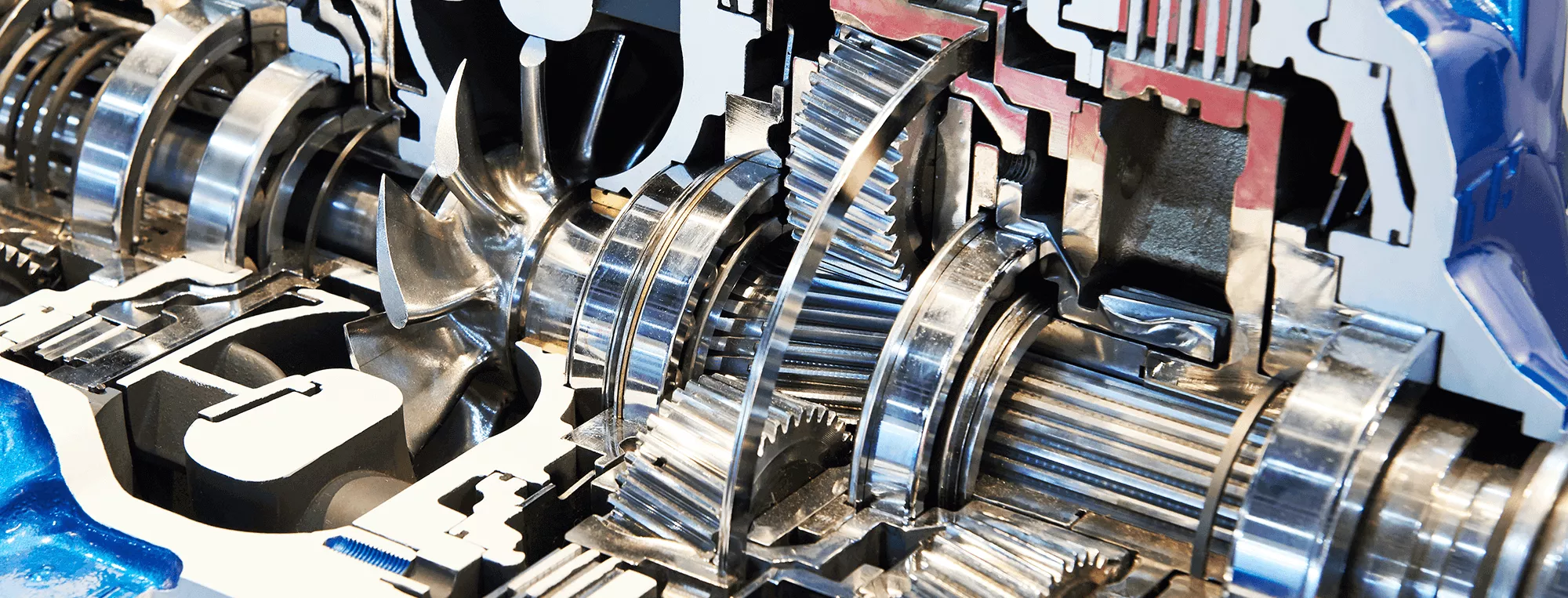

Gearboxes of any type, size and application purpose fulfil one common purpose: They serve to the transmission and conversion of movements and energy in the form of speeds, torques, directions of rotation and forces. What provides for an exact and reliable implementation of these functions is mainly the top-quality, high-performance locking device and coupling components designed by RINGFEDER®. Whether you require high-strength, maintenance-free shrink discs for the ideal mounting of system and gearbox hollow shafts as well as corresponding extensions or vibration-reducing claw couplings for the torsionally flexible connection of the drive motor and gearbox – our solutions consistently designed in compliance with requirements are the preferred choice of globally leading gearbox manufacturers, for which maximum precision, reliability and efficiency are top priority objectives.

Individual Special Solutions for the Largest Gearbox Dimensions

Specially for and in close collaboration with a Brazilian manufacturer of industrial gearboxes, RINGFEDER® has developed a special application solution of a special size. The powerful gearbox was to ensure the reliable transmission of highest torques and was furthermore to be dimensioned for a gearbox hollow shaft with a diameter of 900 millimetres. By the specific selection of the production process and raw material, a corresponding special design of the RfN 4181 shrink disc series was implemented – within an extremely short delivery time and at an exceptionally economical price. When the clamping screws are tightened, the front and rear pressure ring contract via the cone. This generates the desired shrinking of the hollow shaft, causing compression on the solid shaft, which ensures a reliable, friction-locked torque transmission between the system shaft and the hollow shaft. The special solution designed by RINGFEDER® is the largest shrink disc currently installed in Brazil.

Innovative Bushing System as an Alternative to Conventional Locking Devices

The specific application of connecting the hollow shafts to the system shafts in the case of high-torque gearboxes of a leading manufacturer posed an innovative and complex key requirement: Providing for the flexible coverage of solid shafts in different metric and inch-based dimensions via one hollow shaft system without restricting the functionality and performance range of the transmission in comparison to conventional shrink disc connections. For this purpose, RINGFEDER® designed a special modular bushing system together with the customer, which allows for the generation of a frictional clamping connection of shafts with a range of different rated diameters and even less narrowly tolerated surface qualities – and all this providing easy and quick options for assembly and disassembly. The RINGFEDER® shrink discs also used for this system variant are manufactured of high-strength forged rings, in this way obtain maximum attain durability and, when dimensioned optimally, work in an absolutely wear-free and maintenance-free fashion.

Quality Components for Perfect Interaction

In addition to compact, economic and installation-friendly RINGFEDER® shrink discs which are typically used for any type of frictional locking device, elastic RINGFEDER® jaw couplings of the GWE, TNM, TNS and TNB series as well as backlash-free metal bellows couplings of the GWB mainly prove to be the perfect products to be used in the field of gearbox technology. They work with high precision and reliability, effectively compensate for misalignments in all directions and are available to customers in various standard and special designs perfectly tailored to the customers’ applications. One brief example: With a jaw coupling of the TNM GTW model including an integrated brake disc, RINGFEDER® implemented the shaft connection of an industrial gearbox used in the mining sector with a fluid coupling that must meet tremendous requirements with regard to its compactness and rotary vibration damping.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.