Maximum Productivity and Precision

Attaining and ensuring the required precision and desired output quantities are part of the elementary requirements in the segment of machine tools and CNC machining centres – if possible, avoiding cost-intensive maintenance periods and downtimes. This is why globally leading manufacturers bank on backlash-free, torsionally stiff metal bellows couplings, backlash-free, vibration-reducing elastomer couplings, powerful locking devices as well as damping solutions by RINGFEDER®, which contribute substantially to the optimum implementation of these requirements.

Effective Overload Protection in the Smallest Installation Space

Multi-spindle automatic CNC lathes provide for the simultaneous machining of several workpieces in one machine with a high productivity. If the feed axis crashes, for instance because of incorrect operation or incorrect programming, it is damaged, resulting in an operational standstill of the whole machine. In order to prevent such an incident that involves great effort and cost, specially designed RINGFEDER® friction springs are used, reliably protecting the drive spindle against overload-related failures. Friction springs only take up a very small installation space, respond within a few milliseconds and are ready for operation again immediately after being loaded. Even in the unlikely case that one of the damping elements within the spring is damaged it will still remain functional and can be repaired in the course of the next regular maintenance interval.

Reliable Protection in the Event of Malfunctions

Modern CNC machining centres are mostly provided with automated loading and unloading units which feed and discharge components to be processed into and from the workspace. If these units overtravel their defined end positions, e.g. in the case of an abrupt machine fault, this causes substantial damage to the drive of the machine. In order to systematically rule out these negative consequences, internationally leading machine tool manufacturers for example rely on powerful DEFORM plus® impact protection elements designed by RINGFEDER®: Their use effectively protects the drive against potential machine malfunctions and in this way prevents costly repair processes and production downtimes. DEFORM plus® impact protection elements are suitable for maximum high energy absorption, in particular under tight installation conditions, and are extremely installation- and maintenance-friendly thanks to their compact design principle.

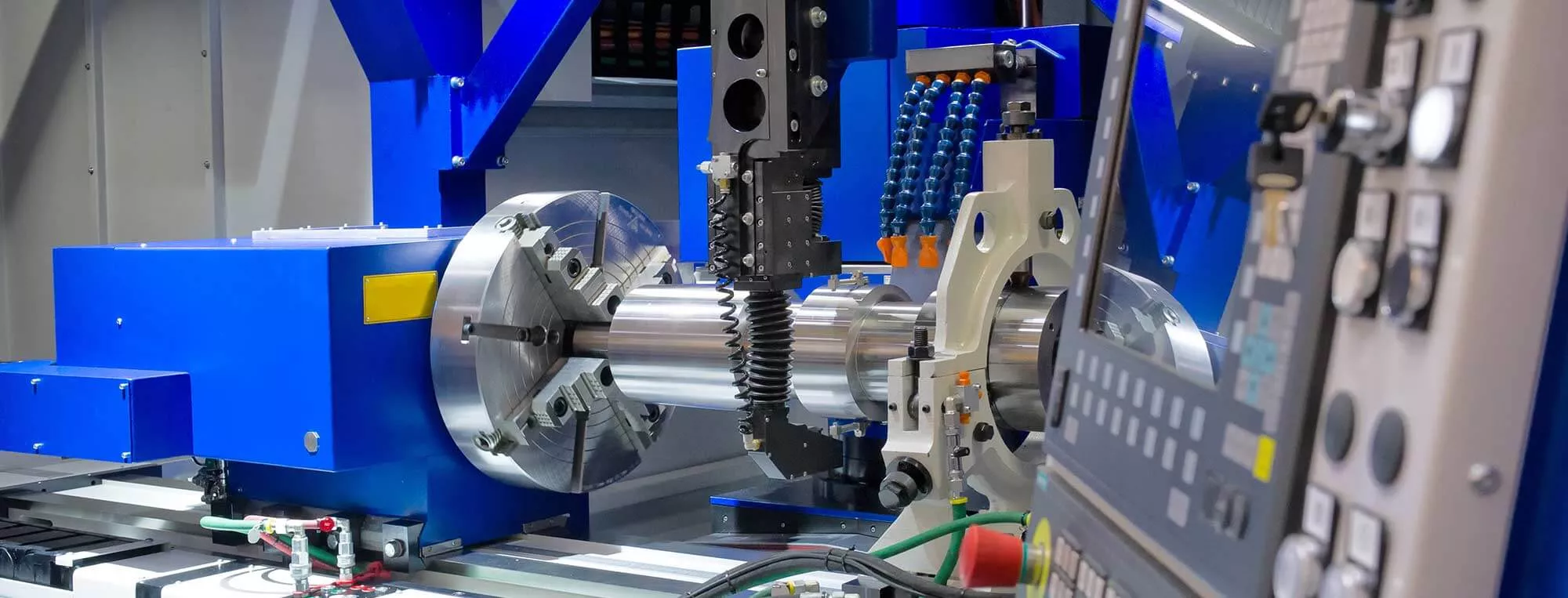

Optimum Connection Between Drive and Main Spindle

Manufacturers set exceptionally high standards with regard to the quality of the connection between the main spindle and the drive of a machine tool: In order to ensure perfect operation of the machine, the connection must provide zero backlash and must be easy to establish. Furthermore, it must meet essential damping functions and compensate various types of misalignments. Specially designed RINGFEDER® elastomer couplings meet these requirements and are therefore the preferred choice of globally leading machine tool manufacturers. Moreover, they also bank on top-quality and durable RINGFEDER® locking devices such as locking assemblies or shrink discs. These backlash-free shaft-hub connections contribute to constantly achieving maximum precision with regard to the components to be manufactured.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.