Durable, Service-Friendly, Tailor-Made: Connection and Damping Elements for Material Handling

Attaining an uninterrupted flow of material and goods is an indispensable priority for added value in almost every industrial sector today. If piece goods (e.g. workpieces, boxes, packages, pallets) or bulk materials (e.g. iron ore, coal, sand) are moved and transported, this requires individually tailored, highly automated transport systems that are as fail-safe as possible – a complex and wide field, ranging from linear drives to transfer gantries and robot systems, including handling and assembly units as well as belt conveyors and roller conveyors. For these uses and for a variety of other applications of industrial materials handling, RINGFEDER® as your system partner offers customised, high-precision coupling, locking device and damping solutions, which are characterised by an exceptional installation and maintenance friendliness as well as outstanding reliability and functionality. Of course, this also applies for fields of application requiring special compliance with safety and hygiene guidelines such as the food and medicine production.

Uninterrupted Performance and Reliability

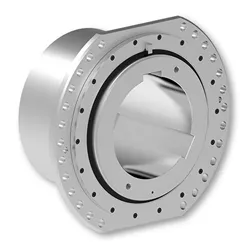

In close cooperation with an internationally leading manufacturer of highly automated production lines for the automotive, rail and aircraft production, RINGFEDER® has implemented a tailor-made special solution: In a modular conveyor system, which feeds car body sheets to several forming plants, specially designed steel disc couplings of the RINGFEDER® TND series serve as torsionally rigid connection elements between between the drive and the roller conveyors as well as between the conveyors themselves – as up to six roller conveyors are provided with just one single drive. The individually designed shaft connectors meet the exceptionally high customer requirements with regard to compactness, the ability of compensating for misalignments, corrosion protection, and transmissible torque, and are furthermore extremely installation- and maintenance-friendly.

Perfect Connection at a Greater Shaft Distance

Transfer machines serve to continuously and automatically transport and position workpieces within a machining centre or between the individual stations of an assembly line production facility consisting of several processing machines. In order to implement a linearly designed transfer machine, which transports brake discs to be manufactured directly into the work space of a processing machine and, following the machining process, transfers them to the next machine downstream, one customer opted for a premium-quality metal bellows coupling of the RINGFEDER® GWE 5106 series – the perfect connection between the brushless drive motor and the threaded spindle. This torsionally rigid coupling solution is provided with an intermediate shaft of aluminium, in order to bridge the greater shaft distance that is typical of this application. Furthermore, it works with zero backlash, effectively compensates for axial, angular and radial alignment errors, offers a high rotation angle accuracy, and it is completely maintenance- and wear-free. In this way, it provides maximum precision and reliability to the user, ensuring maximum operational reliability and productivity.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.