Special Solutions for Special Solutions

Special machines, devices or instruments are individually developed and manufactured so as to meet special customer requests in small batches or exclusively as individual items. In turn, this often requires special components the type and function of which is explicitly attuned to the requirements that are specified. We support customers from the sector of special mechanical engineering all around the globe with our long-standing experience and profound expertise by providing them with durable, user-friendly machine elements which are designed individually and complying with the corresponding request. Whether you’re dealing with highly durable, torsionally stiff multi-plate clutches for tube straightening machines, absolutely backlash-free locking device for cotton production plants or high-performance friction springs for mountain railway systems – no challenge is too quick, too high or too far for RINGFEDER® products.

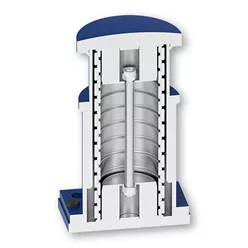

Friction Springs Providing for Concentricity

Commonly, Ferris wheels are the supreme attraction of theme parks and amusement parks and in some well-known cities of the world have even established themselves as famous landmarks that are tourist magnets. Modern designs are usually made of steel and are provided with four inclined beams converging on a non-driven hub. The inevitable problem: The higher a Ferris wheel is, the more the steel construction tends to deviate from optimum concentricity. In order to ensure a constantly even transmission of the actuating power of the electric motors to the impellers of the Ferris wheel nevertheless RINGFEDER® has developed an individual traction device. This device uses a specially designed, maintenance-free friction spring to provide for the flexible adjustability of the traction force and reliably ensures that drive components and output components always remain in contact with each other – even under strong thermal impacts by heat or chilliness, which additionally influence the concentricity of the Ferris wheel.

Powerful, Flexible, Economic

In its more than one hundred test benches for vacuum cleaner motors, an internationally leading manufacturer of electronic housekeeping cleaning devices used extremely stiff couplings for the connections of motor and vacuum cleaner. They were extremely cost-effective and always directly available, however, in continuous use they turned out to be tremendously susceptible to repairs and failures, resulting in regular standstill of individual test benches. The ideal alternative solution: RINGFEDER® metal bellows couplings of the GWB EKN series of top-quality stainless steel, which allowed for an absolute backlash-free torque transmission and which were able to compensate for misalignments in all directions that were caused by inaccurate shaft positioning. Together with the uncomplicated and quick assembly and the substantially lower costs for maintenance and wear, the use of the RINGFEDER® metal bellows couplings brought about a significant increase in the operational safety of all motor test benches.

Absolutely Backlash-Free, Extremely Compact

Many special requests, one appropriate RINGFEDER® solution: In the field of special processing machines, e.g. laser cutting tools, sawing machines or shredders, rotationally elastic jaw coupling of the RINGFEDER® GWE series just as torsionally stiff metal bellows couplings of the RINGFEDER® GWB type are the preferred choice. Intelligently attuned to the specific requirements of the respective application, they prove to be powerful, reliable and compact shaft connections, for instance in main spindle and positioning drives the speeds of which are continuously increasing. They feature ideal damping characteristics, effectively compensate for any misalignments and are extremely installation- and maintenance-friendly.

Suitable Products

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.