Barrel Couplings TNK TKVO

Application and Performance Optimized Type Made of High-Strength Material for Rope Drums in Lifting Units of Cranes and Hoists

- 18 Sizes

- Construction acc. to SEB 666212

- Bore Diameter d1: 20-440 mm (0.787-17.323 inch)

- Outer Diameter D: 250-850 mm (9.843-33.465 inch)

- Overall Length L: 95-450 mm (3.740-17.717 inch)

- Torque TKmax: 6,500-815,000 Nm (4,794.15-601,113.11 ft·lb)

- Max. Radial Load Frad: 17,650-490,000 N (3,966.52-110,118.68 lb)

Product Characteristics

Your Advantages

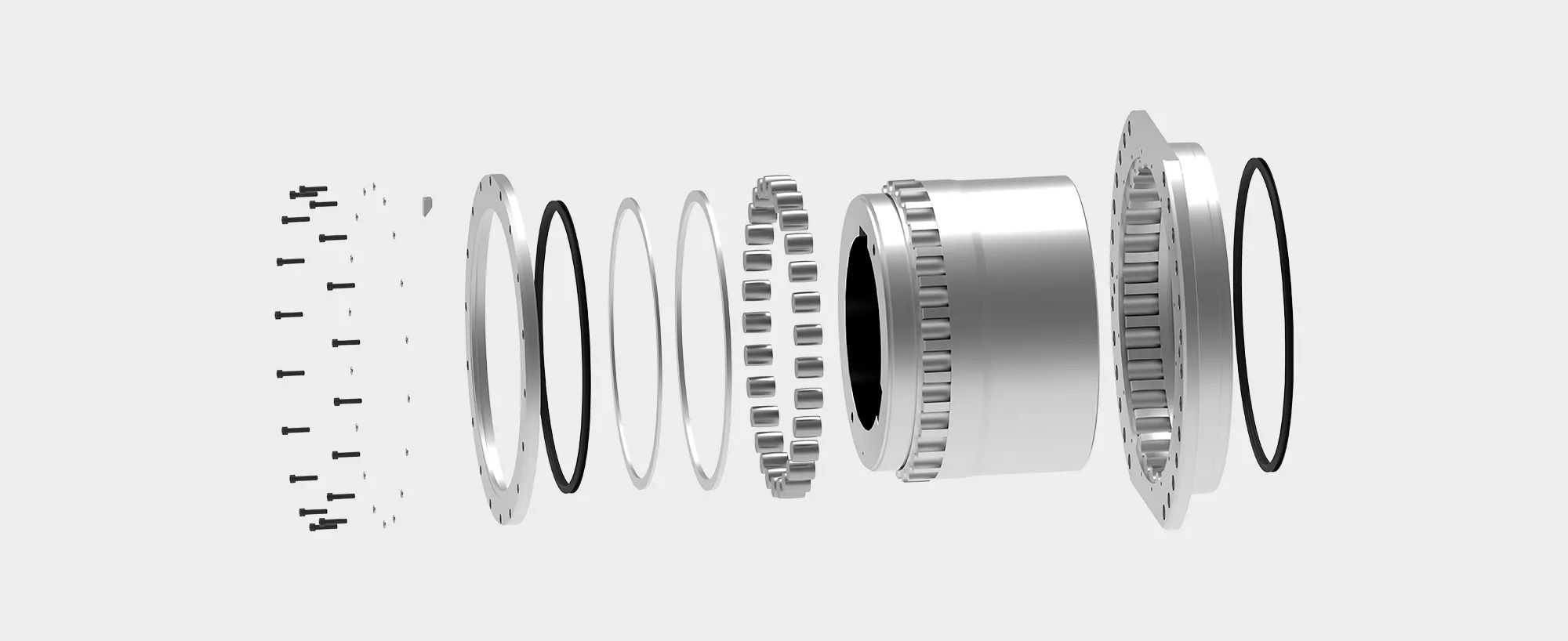

The type RINGFEDER® TNK TKVO is a torsionally stiff barrel coupling with hub and housing made of high strength material. The inner ring integrated in the housing enables quick and easy assembly with an extremely compact coupling design. The type incorporates construction according to the operation sheet of the German Steel Iron Industry SEB 666212 for rope drum hinge joints.

Barrel Couplings of the RINGFEDER® TNK TKVO type are particularly convincing due to the following features:

- Torsionally rigid, compensate for angular and axial shaft misalignment

- Torque transmission by steel rollers

- With standardized connection to rope drums in crane lifting gear

- Reduced assembly effort due to integrated inner ring as well as simplified insertion of the barrel coupling

- With wear indicator for easier condition monitoring

- Bore diameter d1 up to 440 mm (17.323 inch)

- Outer diameter D up to 850 mm (33.465 inch)

- Transmissible torque TKmax up to 815,000 Nm (601,113.11 ft·lb)

- Maximum radial load Frad up to 490,000 N (110,118.68 lb)

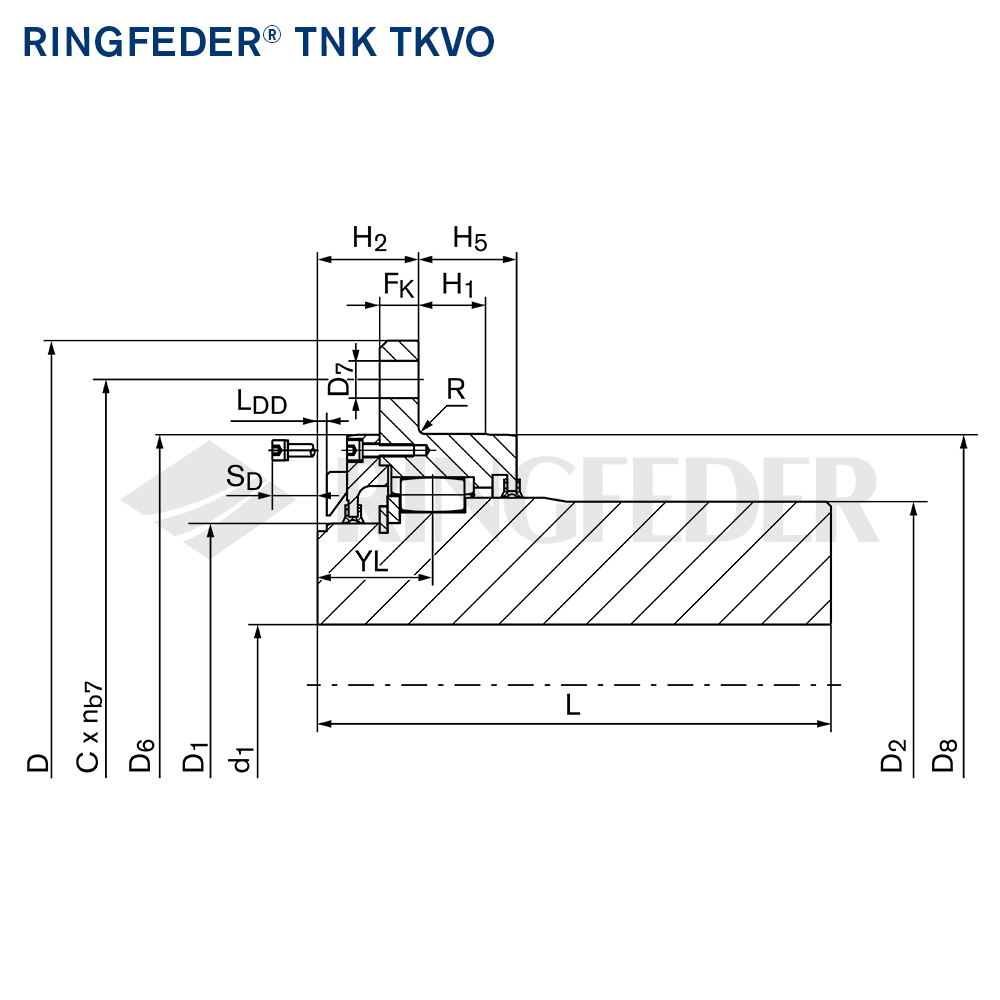

Description & Characteristics

The barrel couplings consist of a housing made of high-strength material equipped with semi-circular internal toothing, and a hub made of high-strength material equipped with semi-circular external toothing of the same shape. Steel barrel rollers are inserted in the resulting circular receptacle to serve as power transmission elements. The inner cover integrated in the housing allows the hub diameter and thus also the bore diameter to be increased and also fixes the barrel roller axially to the drum. Outside the drum, axial fixation is provided by a retaining ring, which is also supported by an additional thrust ring. Lip seals prevent foreign bodies from ingressing or lubricant from leaking out.

The curved shape of the barrel rollers allows the hub to oscillate relative to the housing, thus compensating for angular misalignments. Depending on the coupling size, axial displacements of 3 to 8 mm (0.118 to 0.315 inch) can be accommodated during operation. The torque is transmitted by means of two carrier surfaces on the housing and their counter mating surfaces machined into the drum. The screws used as a connection to the drum facilitate the torque transmission. By using high-strength materials for both hub and housing, transmission capabilities could be increased significantly compared to earlier coupling types.

Main Areas of Use

- Hoists

- Winches

- Conveyor Belts & Systems

Application

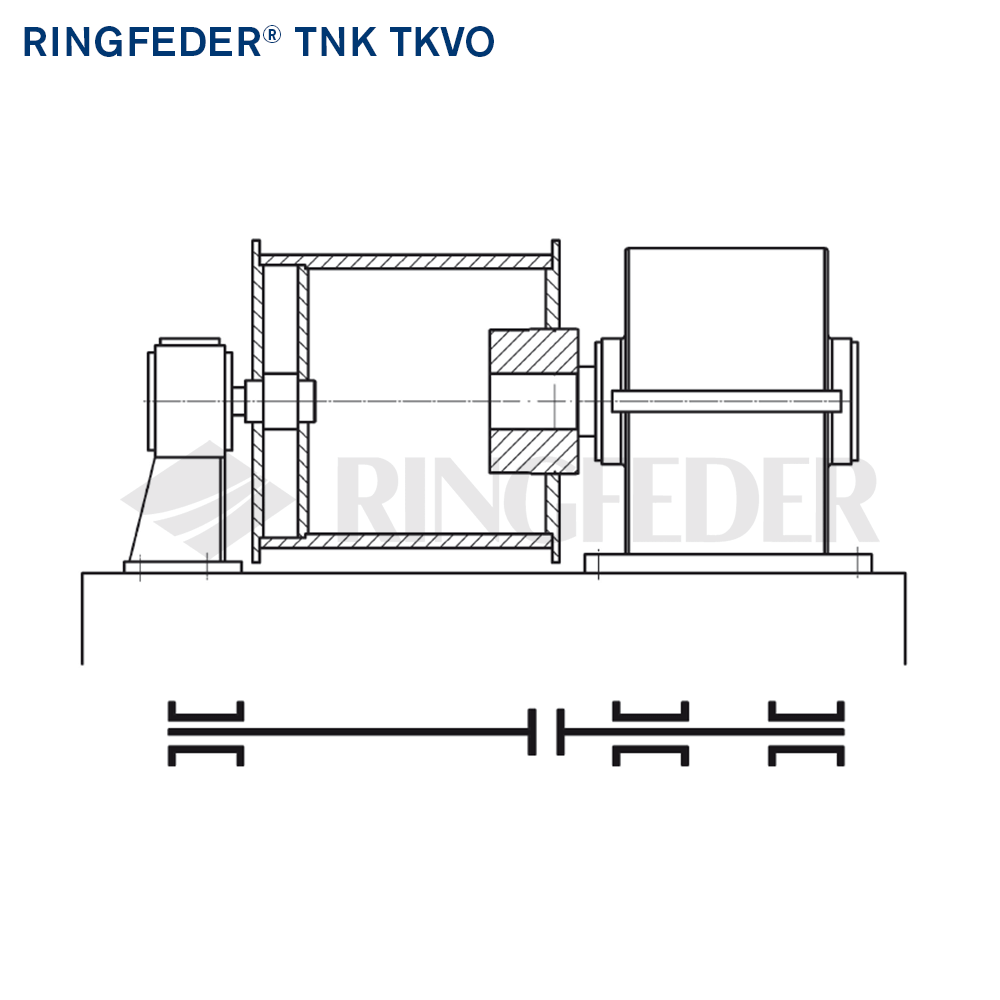

Barrel couplings are used in material handling technology, especially in crane hoists, to connect the rope drum to the gearbox output shaft with minimum axial installation space. In this application, the barrel coupling transmits high torques and large radial forces, and acts as a joint. Thus, a rigid connection of the gear shaft to a hoist drum would result in a statically indeterminate case due to the three-point bearings (Figure No. 1). In that case, a high quality of alignment is required. However, unavoidable mounting inaccuracies, deflection of the steel structure under load, and rolling bearing wear occurring with use cause a positional misalignment, resulting enormous restoring forces that have to be absorbed by the gear shaft bearing. Alternating bending stresses can lead to fatigue failure as well as bearing and gear damage.

To avoid this risk, barrel couplings are interposed between the gear unit and the rope drum, which, due to their characteristics, compensate misalignments angularly. This additional joint turns a three-point bearing arrangement into a statically determined drive train, thus avoiding misalignment-related bending moments and constraining forces.

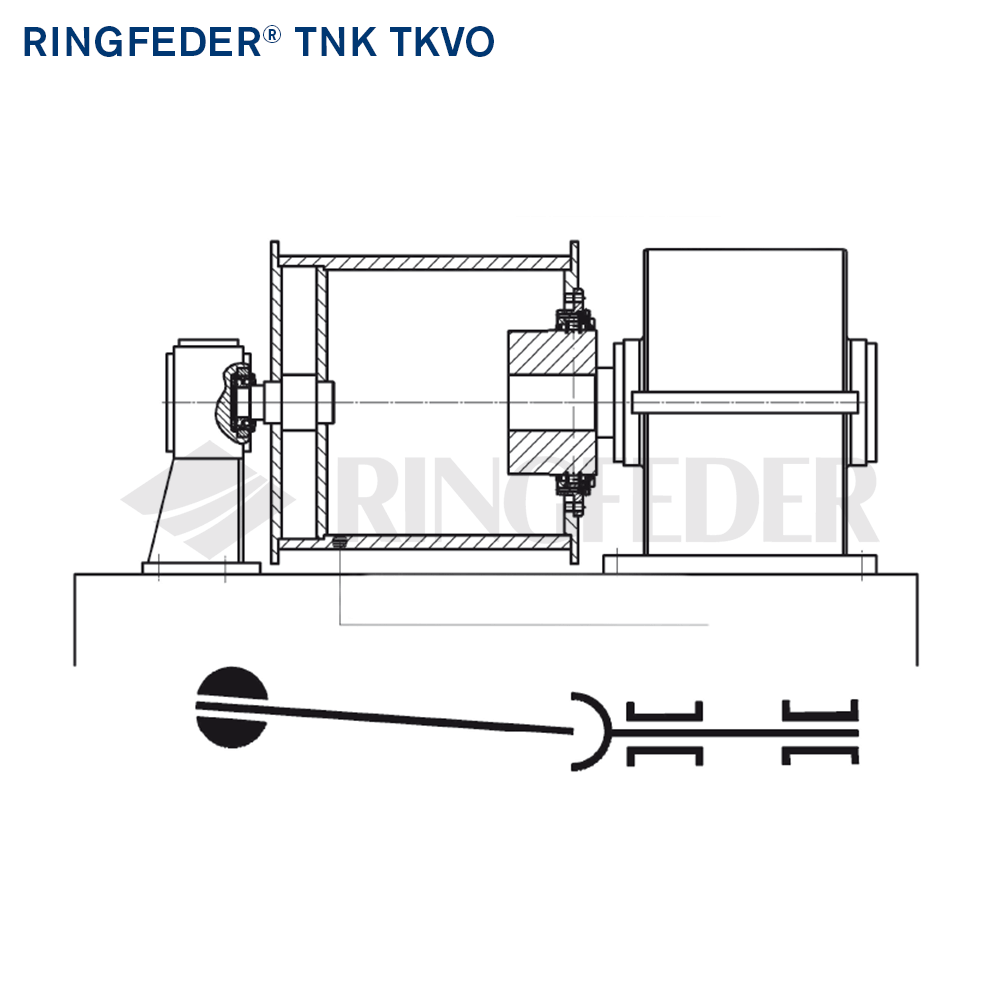

Figure No. 2 shows the assembly of a barrel coupling in a hoist. Considering that the coupling absorbs axial displacements and thus acts as a floating bearing, a spherical roller bearing must be provided as a locating bearing at the other end of the drum shaft.

Technical Information

Moreover, please observe the detailed selection and operating criteria in the documents Product Paper Barrel Couplings RINGFEDER® TNK and Tech Paper Barrel Couplings RINGFEDER® TNK TKVO.

Technical Data & CAD Models

You require CAD data for this TNK type? Of course, we are more than happy to provide you with these. Contact us quickly and easily via our request form, by e-mail or using the "Need Help?" feature at the bottom right of this site.

| CAD |

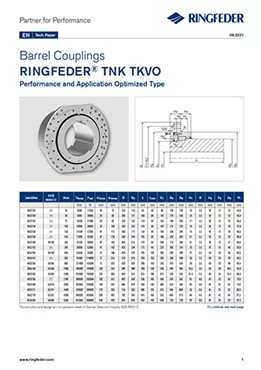

Bezeichnung / Identifier

|

SEB 666212

|

Größe/Size

|

TKmax

Nm |

Frad

N |

d1kmin

mm |

d1kmax

mm |

D

mm |

D2

mm |

L

mm |

Lmin

mm |

D1

mm |

H2

mm |

FK

mm |

C

mm |

Gwsb

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WG3125 | (*) | 25 | 6500 | 17650 | 20 | 70 | 250 | 110 | 95 | 85 | 95 | 42 | 12 | 220 | 13 | |

| WG3128 | (*) | 50 | 8400 | 20000 | 20 | 80 | 280 | 127 | 100 | 85 | 110 | 42 | 12 | 250 | 17 | |

| WG3132 | (*) | 75 | 10500 | 21500 | 20 | 90 | 320 | 142 | 110 | 95 | 125 | 45 | 15 | 280 | 24 | |

| WG3134 | (*) | 100 | 16000 | 28000 | 20 | 100 | 340 | 155 | 125 | 95 | 140 | 45 | 15 | 300 | 32 | |

| WG3136 | (*) | 130 | 21500 | 37000 | 47 | 115 | 360 | 175 | 130 | 95 | 160 | 45 | 15 | 320 | 38 | |

| WG3138 | (*) | 160 | 27000 | 42500 | 47 | 130 | 380 | 194 | 145 | 95 | 180 | 45 | 15 | 340 | 48 | |

| WG3140 | SG130 | 200 | 31500 | 48000 | 47 | 145 | 400 | 213 | 170 | 95 | 200 | 45 | 15 | 360 | 64 | |

| WG3142 | (*) | 300 | 39000 | 53000 | 47 | 160 | 420 | 234 | 175 | 95 | 220 | 45 | 15 | 380 | 79 | |

| WG3145 | SG140 | 400 | 53500 | 75000 | 47 | 190 | 450 | 274 | 185 | 120 | 260 | 60 | 20 | 400 | 108 | |

| WG3151 | (*) | 500 | 91000 | 118000 | 77 | 215 | 510 | 314 | 220 | 125 | 295 | 60 | 20 | 460 | 163 | |

| WG3155 | SG185 | 600 | 127000 | 132000 | 77 | 225 | 550 | 329 | 240 | 125 | 310 | 60 | 20 | 500 | 195 | |

| WG3158 | SG200 | 1000 | 180000 | 145000 | 102 | 255 | 580 | 368 | 260 | 130 | 350 | 60 | 20 | 530 | 244 | |

| WG3165 | SG240 | 1500 | 241000 | 184000 | 102 | 305 | 650 | 431 | 315 | 140 | 415 | 65 | 25 | 600 | 404 | |

| WG3166 | (*) | 2100 | 360000 | 283000 | 102 | 315 | 665 | 458 | 330 | 145 | 430 | 65 | 25 | 615 | 467 | |

| WG3168 | SG270 | 2600 | 425000 | 330000 | 102 | 325 | 680 | 470 | 350 | 145 | 445 | 65 | 25 | 630 | 520 | |

| WG3171 | SG315 | 3400 | 529000 | 366000 | 178 | 350 | 710 | 502 | 380 | 165 | 475 | 81 | 35 | 660 | 598 | |

| WG3178 | SG355 | 4200 | 660000 | 420000 | 208 | 395 | 780 | 566 | 410 | 165 | 535 | 81 | 35 | 730 | 795 | |

| WG3185 | SG400 | 6200 | 815000 | 490000 | 238 | 440 | 850 | 630 | 450 | 165 | 600 | 81 | 35 | 800 | 1049 |

| CAD |

Bezeichnung / Identifier |

SEB 666212 |

Größe/Size |

TKmax ft-lbs |

Frad lbs |

d1kmin inch |

d1kmax inch |

D inch |

D2 inch |

L inch |

Lmin inch |

D1 inch |

H2 inch |

FK inch |

C inch |

Gwsb lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WG3125 | (*) | 25 | 4794.205 | 3966.520 | 0.787 | 2.756 | 9.843 | 4.331 | 3.740 | 3.346 | 3.740 | 1.654 | 0.472 | 8.661 | 28.660 | |

| WG3128 | (*) | 50 | 6195.588 | 4494.640 | 0.787 | 3.150 | 11.024 | 5.000 | 3.937 | 3.346 | 4.331 | 1.654 | 0.472 | 9.843 | 37.479 | |

| WG3132 | (*) | 75 | 7744.485 | 4831.738 | 0.787 | 3.543 | 12.598 | 5.591 | 4.331 | 3.740 | 4.921 | 1.772 | 0.591 | 11.024 | 52.911 | |

| WG3134 | (*) | 100 | 11801.120 | 6292.496 | 0.787 | 3.937 | 13.386 | 6.102 | 4.921 | 3.740 | 5.512 | 1.772 | 0.591 | 11.811 | 70.548 | |

| WG3136 | (*) | 130 | 15857.755 | 8315.084 | 1.850 | 4.528 | 14.173 | 6.890 | 5.118 | 3.740 | 6.299 | 1.772 | 0.591 | 12.598 | 83.776 | |

| WG3138 | (*) | 160 | 19914.390 | 9551.110 | 1.850 | 5.118 | 14.961 | 7.638 | 5.709 | 3.740 | 7.087 | 1.772 | 0.591 | 13.386 | 105.822 | |

| WG3140 | SG130 | 200 | 23233.455 | 10787.136 | 1.850 | 5.709 | 15.748 | 8.386 | 6.693 | 3.740 | 7.874 | 1.772 | 0.591 | 14.173 | 141.096 | |

| WG3142 | (*) | 300 | 28765.230 | 11910.796 | 1.850 | 6.299 | 16.535 | 9.213 | 6.890 | 3.740 | 8.661 | 1.772 | 0.591 | 14.961 | 174.165 | |

| WG3145 | SG140 | 400 | 39459.995 | 16854.900 | 1.850 | 7.480 | 17.717 | 10.787 | 7.283 | 4.724 | 10.236 | 2.362 | 0.787 | 15.748 | 238.099 | |

| WG3151 | (*) | 500 | 67118.870 | 26518.376 | 3.031 | 8.465 | 20.079 | 12.362 | 8.661 | 4.921 | 11.614 | 2.362 | 0.787 | 18.110 | 359.354 | |

| WG3155 | SG185 | 600 | 93671.390 | 29664.624 | 3.031 | 8.858 | 21.654 | 12.953 | 9.449 | 4.921 | 12.205 | 2.362 | 0.787 | 19.685 | 429.902 | |

| WG3158 | SG200 | 1000 | 132762.600 | 32586.140 | 4.016 | 10.039 | 22.835 | 14.488 | 10.236 | 5.118 | 13.780 | 2.362 | 0.787 | 20.866 | 537.928 | |

| WG3165 | SG240 | 1500 | 177754.370 | 41350.688 | 4.016 | 12.008 | 25.591 | 16.968 | 12.402 | 5.512 | 16.339 | 2.559 | 0.984 | 23.622 | 890.668 | |

| WG3166 | (*) | 2100 | 265525.200 | 63599.156 | 4.016 | 12.402 | 26.181 | 18.031 | 12.992 | 5.709 | 16.929 | 2.559 | 0.984 | 24.213 | 1029.560 | |

| WG3168 | SG270 | 2600 | 313467.250 | 74161.560 | 4.016 | 12.795 | 26.772 | 18.504 | 13.780 | 5.709 | 17.520 | 2.559 | 0.984 | 24.803 | 1146.405 | |

| WG3171 | SG315 | 3400 | 390174.530 | 82251.912 | 7.008 | 13.780 | 27.953 | 19.764 | 14.961 | 6.496 | 18.701 | 3.189 | 1.378 | 25.984 | 1318.365 | |

| WG3178 | SG355 | 4200 | 486796.200 | 94387.440 | 8.189 | 15.551 | 30.709 | 22.283 | 16.142 | 6.496 | 21.063 | 3.189 | 1.378 | 28.740 | 1752.676 | |

| WG3185 | SG400 | 6200 | 601119.550 | 110118.680 | 9.370 | 17.323 | 33.465 | 24.803 | 17.717 | 6.496 | 23.622 | 3.189 | 1.378 | 31.496 | 2312.651 |

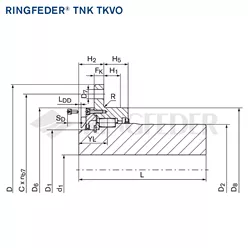

Images & Drawings

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.