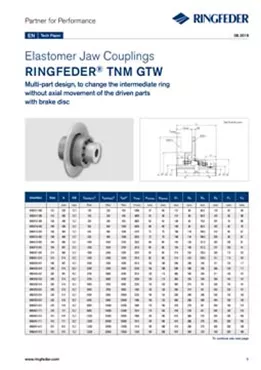

Elastomer Jaw Couplings TNM GTW

THREE-part design brake disk made of nodular graphite iron

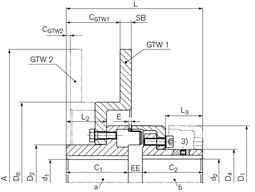

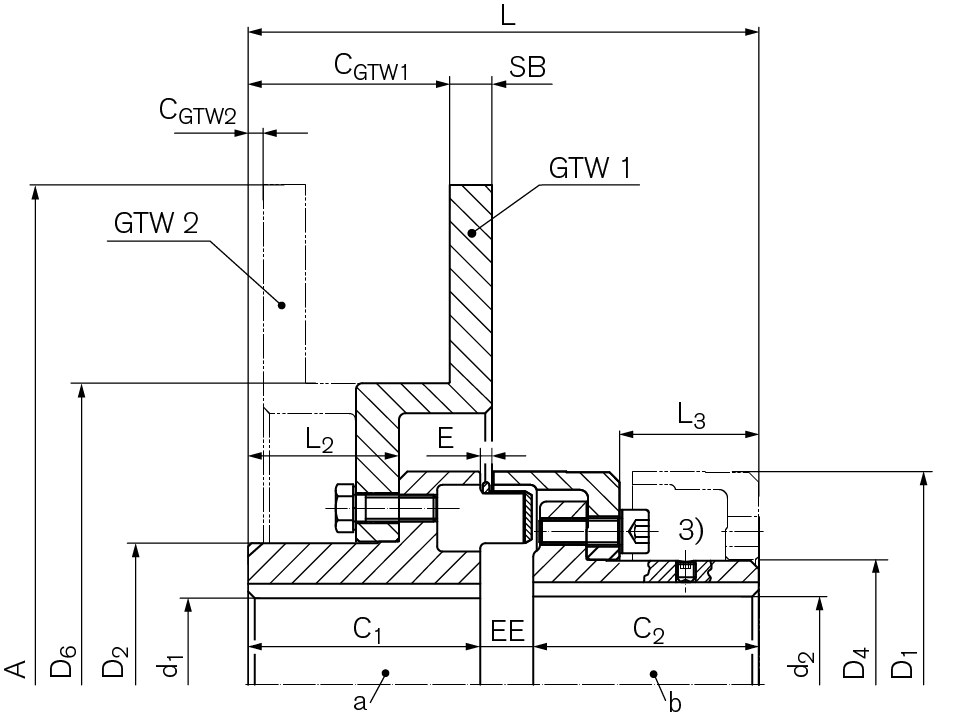

The RINGFEDER® TNM GTW is an torsionally flexible and shock-proof claw coupling with brake disc and removable claw ring. They compensate for angular as well as radial and axial shaft misalignment within fixed tolerances. The torque is transmitted through an elastic transitional ring. The elastic transitional ring made of synthetic rubber (Pb) dampens shocks and torsional vibrations, is oil-resistant and normally electrically conductive. This prevents undesirable static charging, among other things. The coupling can be used for either direction of rotation and be installed in any position. One coupling half consists of a hub and a bolt on claw ring, for easy separation of the coupled machine. With the claw ring unbolted and slid back, a check of the rotational direction of the drive is possible. In the same manner, a coupling half with the associated aggregate can be removed radially. The elastic transitional ring permits replacing of machines without axial displacement.

Technical Data & CAD Models

| CAD |

Identifier

|

A

mm |

SB

mm |

TKNPb82

Nm |

TBR

Nm |

nmax

1/min |

d1kmax

mm |

d2kmax

mm |

C1

mm |

C2

mm |

L

mm |

Gwub

kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WN0411-250 | 250 | 12,7 | 230 | 450 | 4580 | 42 | 46 | 60 | 58 | 133 | 8,8 | |

| WN0411-300 | 300 | 12,7 | 230 | 450 | 3820 | 42 | 46 | 60 | 58 | 133 | 11,7 | |

| WN0412-300 | 300 | 12,7 | 380 | 550 | 3820 | 52 | 53 | 70 | 68 | 154 | 14,6 | |

| WN0414-300 | 300 | 12,7 | 600 | 1000 | 3820 | 58 | 65 | 80 | 78 | 176 | 18,4 | |

| WN0416-356 | 356 | 12,7 | 980 | 1600 | 3225 | 72 | 75 | 90 | 87 | 198 | 28,0 | |

| WN0416-406 | 406 | 12,7 | 980 | 1600 | 2825 | 72 | 75 | 90 | 87 | 198 | 31,0 | |

| WN0419-406 | 406 | 12,7 | 1650 | 2750 | 2825 | 85 | 85 | 100 | 97 | 221 | 39,1 | |

| WN0419-457 | 457 | 12,7 | 1650 | 2750 | 2510 | 85 | 85 | 100 | 97 | 221 | 44,0 | |

| WN0421-406 | 406 | 12,7 | 2400 | 3350 | 2825 | 92 | 95 | 110 | 107 | 243 | 48,8 | |

| WN0421-514 | 514 | 12,7 | 2400 | 3350 | 2510 | 92 | 95 | 110 | 107 | 243 | 53,6 | |

| WN0424-457 | 457 | 12,7 | 3700 | 4200 | 2510 | 102 | 100 | 120 | 117 | 267 | 67,0 | |

| WN0424-514 | 514 | 12,7 | 3700 | 4200 | 2230 | 102 | 100 | 120 | 117 | 267 | 72,0 | |

| WN0426-457 | 457 | 12,7 | 5800 | 8700 | 2510 | 120 | 115 | 140 | 137 | 310 | 89,4 | |

| WN0426-514 | 514 | 12,7 | 5800 | 8700 | 2230 | 120 | 115 | 140 | 137 | 310 | 94,2 | |

| WN0429-514 | 514 | 12,7 | 7550 | 9800 | 2230 | 130 | 130 | 150 | 147 | 334 | 113,5 | |

| WN0429-610 | 610 | 12,7 | 7550 | 9800 | 1880 | 130 | 130 | 150 | 147 | 334 | 124,5 | |

| WN0433-514 | 514 | 12,7 | 9900 | 10600 | 2230 | 150 | 135 | 160 | 156 | 356 | 149,3 | |

| WN0433-610 | 610 | 12,7 | 9900 | 10600 | 1880 | 150 | 135 | 160 | 156 | 356 | 160,3 | |

| WN0437-610 | 610 | 12,7 | 14000 | 13500 | 1880 | 170 | 160 | 180 | 176 | 399 | 212,7 | |

| WN0437-711 | 711 | 12,7 | 14000 | 13500 | 1615 | 170 | 160 | 180 | 176 | 399 | 227,9 | |

| WN0441-610 | 610 | 12,7 | 20500 | 16000 | 1880 | 185 | 180 | 200 | 196 | 441 | 279,5 | |

| WN0441-711 | 711 | 12,7 | 20500 | 16000 | 1615 | 185 | 180 | 200 | 196 | 441 | 294,3 | |

| WN0441-812 | 812 | 12,7 | 20500 | 16000 | 1410 | 185 | 180 | 200 | 196 | 441 | 326,4 | |

| WN0441-915 | 915 | 12,7 | 20500 | 16000 | 1255 | 185 | 180 | 200 | 196 | 441 | 356,8 |

| CAD |

Identifier |

A inch |

SB inch |

TKNPb82 ft-lbs |

TBR ft-lbs |

nmax rpm |

d1kmax inch |

d2kmax inch |

C1 inch |

C2 inch |

L inch |

Gwub lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WN0411-250 | 9.843 | 0.50 | 170 | 332 | 4580 | 1.65354 | 1.81102 | 2.362 | 2.283 | 5.236 | 19.40 | |

| WN0411-300 | 11.811 | 0.50 | 170 | 332 | 3820 | 1.65354 | 1.81102 | 2.362 | 2.283 | 5.236 | 25.79 | |

| WN0412-300 | 11.811 | 0.50 | 280 | 406 | 3820 | 2.04724 | 2.08661 | 2.756 | 2.677 | 6.063 | 32.19 | |

| WN0414-300 | 11.811 | 0.50 | 443 | 738 | 3820 | 2.28346 | 2.55905 | 3.150 | 3.071 | 6.929 | 40.57 | |

| WN0416-356 | 14.016 | 0.50 | 723 | 1180 | 3225 | 2.83464 | 2.95275 | 3.543 | 3.425 | 7.795 | 61.73 | |

| WN0416-406 | 15.984 | 0.50 | 723 | 1180 | 2825 | 2.83464 | 2.95275 | 3.543 | 3.425 | 7.795 | 68.34 | |

| WN0419-406 | 15.984 | 0.50 | 1217 | 2028 | 2825 | 3.34645 | 3.34645 | 3.937 | 3.819 | 8.701 | 86.20 | |

| WN0419-457 | 17.992 | 0.50 | 1217 | 2028 | 2510 | 3.34645 | 3.34645 | 3.937 | 3.819 | 8.701 | 97.00 | |

| WN0421-406 | 15.984 | 0.50 | 1770 | 2471 | 2825 | 3.62204 | 3.74015 | 4.331 | 4.213 | 9.567 | 107.59 | |

| WN0421-514 | 20.236 | 0.50 | 1770 | 2471 | 2510 | 3.62204 | 3.74015 | 4.331 | 4.213 | 9.567 | 118.17 | |

| WN0424-457 | 17.992 | 0.50 | 2729 | 3098 | 2510 | 4.01574 | 3.937 | 4.724 | 4.606 | 10.512 | 147.71 | |

| WN0424-514 | 20.236 | 0.50 | 2729 | 3098 | 2230 | 4.01574 | 3.937 | 4.724 | 4.606 | 10.512 | 158.73 | |

| WN0426-457 | 17.992 | 0.50 | 4278 | 6417 | 2510 | 4.7244 | 4.52755 | 5.512 | 5.394 | 12.205 | 197.09 | |

| WN0426-514 | 20.236 | 0.50 | 4278 | 6417 | 2230 | 4.7244 | 4.52755 | 5.512 | 5.394 | 12.205 | 207.68 | |

| WN0429-514 | 20.236 | 0.50 | 5569 | 7228 | 2230 | 5.1181 | 5.1181 | 5.906 | 5.787 | 13.150 | 250.22 | |

| WN0429-610 | 24.016 | 0.50 | 5569 | 7228 | 1880 | 5.1181 | 5.1181 | 5.906 | 5.787 | 13.150 | 274.48 | |

| WN0433-514 | 20.236 | 0.50 | 7302 | 7818 | 2230 | 5.9055 | 5.31495 | 6.299 | 6.142 | 14.016 | 329.15 | |

| WN0433-610 | 24.016 | 0.50 | 7302 | 7818 | 1880 | 5.9055 | 5.31495 | 6.299 | 6.142 | 14.016 | 353.40 | |

| WN0437-610 | 24.016 | 0.50 | 10326 | 9957 | 1880 | 6.6929 | 6.2992 | 7.087 | 6.929 | 15.709 | 468.92 | |

| WN0437-711 | 27.992 | 0.50 | 10326 | 9957 | 1615 | 6.6929 | 6.2992 | 7.087 | 6.929 | 15.709 | 502.43 | |

| WN0441-610 | 24.016 | 0.50 | 15120 | 11801 | 1880 | 7.28345 | 7.0866 | 7.874 | 7.717 | 17.362 | 616.19 | |

| WN0441-711 | 27.992 | 0.50 | 15120 | 11801 | 1615 | 7.28345 | 7.0866 | 7.874 | 7.717 | 17.362 | 648.82 | |

| WN0441-812 | 31.968 | 0.50 | 15120 | 11801 | 1410 | 7.28345 | 7.0866 | 7.874 | 7.717 | 17.362 | 719.59 | |

| WN0441-915 | 36.024 | 0.50 | 15120 | 11801 | 1255 | 7.28345 | 7.0866 | 7.874 | 7.717 | 17.362 | 786.61 |

Images & Drawings

Product Characteristics

RINGFEDER® TNM GTW

Three-part design, to change the intermediate ring without axial movement of the driven parts with brake disk in nodular cast iron. Elastic intermediate ring in different hardnesses: standard Pb72, hard Pb82.

General features

- Torsionally flexible, compensate for angular, radial and axial shaft misalignment

- Intermediate rings loaded in compression

- Elastomers available in various shore hardness degrees

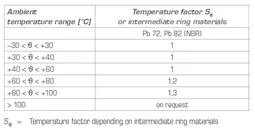

- Suitable for temperatures from –30°C to +100°C

- The elastic ring can be replaced without having to move the coupled machines (multi-part models)

- Bores up to max. 180 mm

- Torques up to TKn = 20,500 Nm / TKmax = 49,000 Nm

- Speeds up to nmax = 4,580 rpm

INTRODUCTION

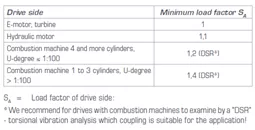

The rotationally resilient coupling of the RINGFEDER® TNM series is flexible in all directions and therefore compensates for angular, parallel and axial shaft misalignments of the connected machines. Misalignments can be caused, for example, by inaccurate assembly, heat movements or settling phenomena.

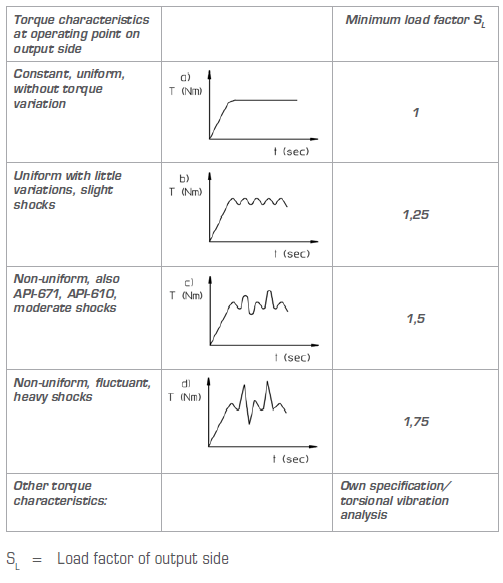

Avoiding Torsional Vibration

By virtue of the rotational resilience of the coupling, dangerous torsional vibrations from the operational range of plant machinery can be transferred to rotational speed ranges in which no negative effects are to be expected. The elastic intermediate rings possess a high material damping capability which makes it possible for the couplings to keep the resonance enhancements within limits when passing through dangerous speed ranges, thereby protecting the coupled machines against damage. The couplings also mitigate torque shocks and cause a vibrating system that has been excited by an impact to come to rest very quickly due to the material damping qualities. The conduction of structure-borne noise is prevented.

Elastomer Materials

Synthetic rubbers are used for the elastic elements of the TNM couplings. As a rule these are electrically conductive and therefore prevent undesirable static charges. For the elastic elements of the RINGFEDER® TNM coupling series, there are two different material hardnesses available as standard.

Pb 72 - nitrile butadien rubber (NBR) with a hardness of 72 Shore A.

Pb 82 - nitrile butadien rubber (NBR) with a hardness of 82 Shore A.

The resilience of the individual elastomer materials is designated by their Shore hardness. From these values an indirect conclusion can be drawn with respect to the torques the coupling is able to transmit and its spring stiffness. For further details, please see the technical data sheet.

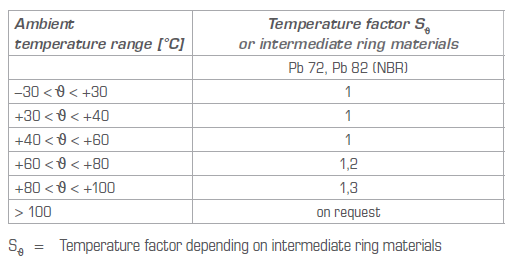

Environmental conditions

The employed elastomer materials operate reliably in ambient temperature ranges of –30° to +100°C. Please contact RINGFEDER POWER TRANSMISSION if higher ambient temperatures are involved. The influence of the temperature on the coupling size selection is explained in more detail in the below-mentioned design directives. It is only allowed to operate the coupling in normal industrial air. Aggressive media may attack the coupling components, bolts and elastic elements, and, therefore, present a danger to the operational safety of the coupling. The coupling can be declared compliant with the European Directive 2014/34/EU (ATEX). Please contact RINGFEDER POWER TRANSMISSION regarding the declaration of conformity according to 2014/34/EU and the effects of aggressive ambient media.

Downloads

Product Paper Elastomer Jaw Couplings RINGFEDER® GWE, TNM, TNS, TNB

Tech Paper Elastomer Jaw Couplings RINGFEDER® TNM GTW

Instruction Manual Elastomer Jaw Couplings RINGFEDER® TNM GBT, TNM GTW

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

Downloads