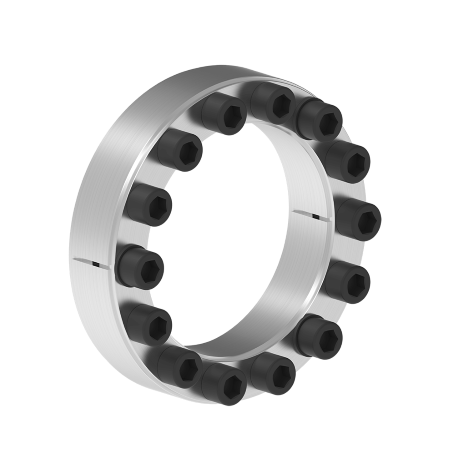

Locking Assemblies RfN 7012

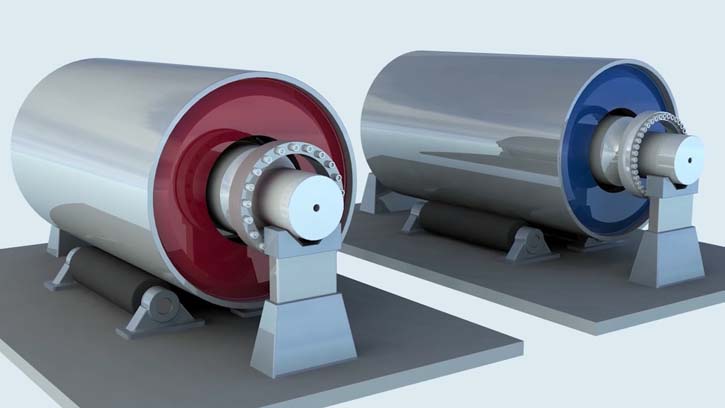

The original RINGFEDER® Locking Assemblies featuring double-tapered thrust rings with self-releasing tapers. They bridge relatively large fit clearances, are easy to install, adjust or remove, but are not self-centering. A pre-centering hub section is usually required.

ℹ This series is also available in true inch sizes.

Product Characteristics

- Slimmest design, especially suitable for applications where space is limited. The Locking Assembly RfN 7012 compensates small tolerance deviations and compensates small mounting errors.

- Large transmittable forces and moments – several Locking Assemblies RfN 7012 can be placed one behind the other. The transmissible torque and axial forces are added - please take in this respect consulting with our technical experts.

- Bending moment and radial loads – combined loads can be transmitted. (Please contact our technical department for assistance).

- Easy installation – RfN 7012 Locking Assemblies can bridge large clearances without the loss of transmission values.

- Low risk to contamination – during the tightening process the functional surfaces of the device and connection are pressed together generating a surface pressure that does not allow the ingress of contamination.

- Free from wear – the Locking Assembly RfN 7012 works without moving parts on shaft and hub, through this, abrasive wear and backlash are avoided. Thus, RfN 7012 can be repeatedly clamped and released.

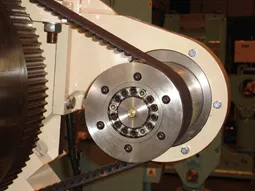

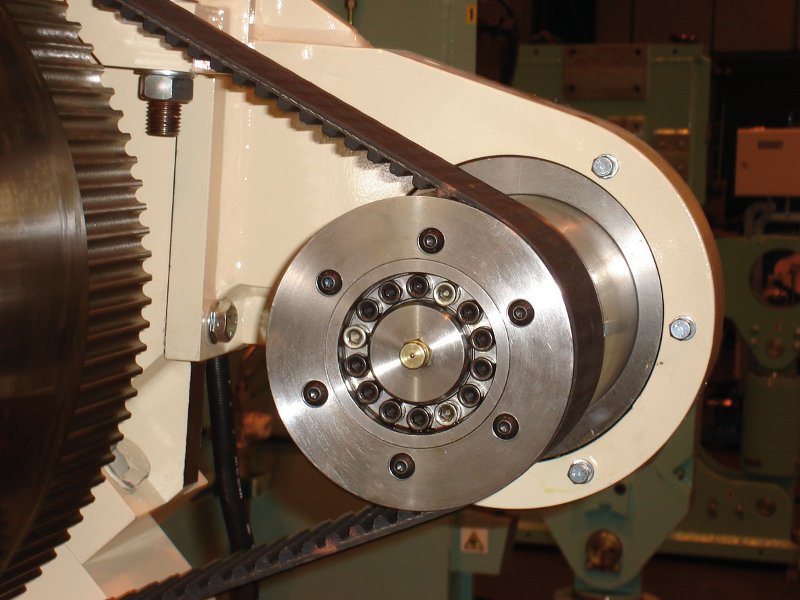

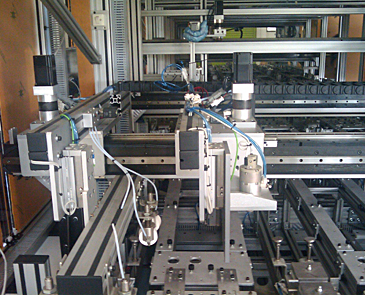

Example applications

- chain wheels

- levers

- pulleys

- slip-on gear mechanisms

- belt drums

- running wheels

- cable sheaves

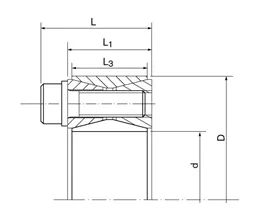

Mounting of Locking Assembly

The Locking Assemblies are supplied slightly oiled and ready-to-use. The values for T, Fax, pW and pN apply to Locking Assemblies in delivery condition.

Surface finishes

For shafts and hub bores Ra = 3,2 μm

Tolerances

We recommend the following mounting tolerances

Shaft: k9-h9; Hub: N9-H9

Max. admissible Shaft: k11-h11; Hub: N11-H11

To avoid excessive deformations of the relatively thickwalled thrust rings, the Locking Assembly should be located as symmetrically as possible between shaft and hub bore. If the shaft is smaller than nominal d, the bore should exceed nominal D to the same extent and vice versa. The concentricity quality is determined by the direct centering between shaft and hub.

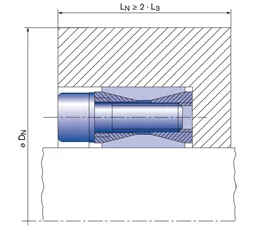

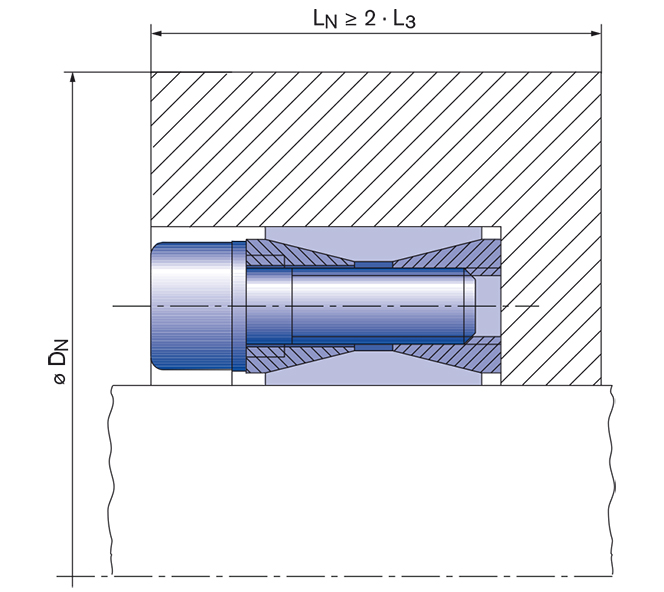

Arrangement of several Locking Assemblies RfN 7012

If several Locking Assemblies are to be installed the transmission values of the table can be added when the Locking Assemblies are located within a distance of 4·L.

Change of screw tightening torques

The Locking Assemblies are equipped with 12.9 grade screws. A reduction of the screw tightening torque is possible. The lowest allowable screw tightening torque results from the multiplication of the TA-value by 0,5. There is an approximate linear relationship between T, TA , Fax, pW and pN.

Auxiliary threads

To facilitate removal, the front thrust rings have auxiliary threads.

360° Product View

Tap and rotate the XR Model below and experience RINGFEDER® RfN 7012 in an interactive, touch-enabled 360° Product View. To access full-screen mode on your laptop or desktop device, simply double-click on the product.

Technical Data & CAD Models

| CAD |

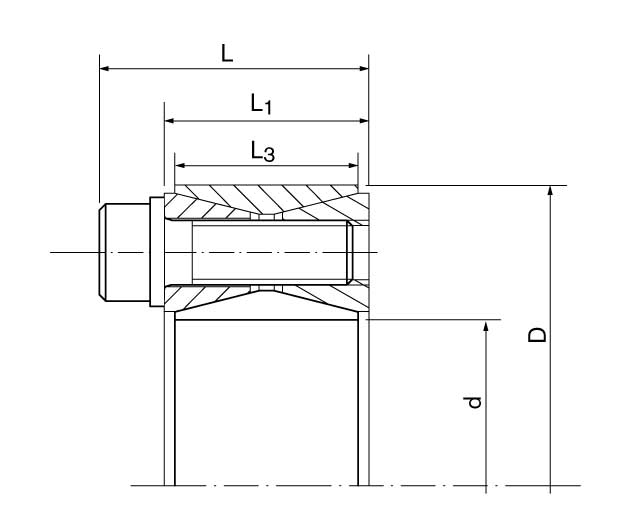

d

mm |

D

mm |

L

mm |

L1

mm |

L3

mm |

T

Nm |

pW

N/mm2 |

pN

N/mm2 |

DG

mm |

TA

Nm |

DN min bei Rp0,2 400 N/mm2

mm |

Tmax

Nm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 47 | 27,5 | 20 | 17 | 306 | 265 | 107 | 6 | 17 | 56 | 356 | |

| 20 | 47 | 27,5 | 20 | 17 | 321 | 251 | 107 | 6 | 17 | 56 | 374 | |

| 22 | 47 | 27,5 | 20 | 17 | 351 | 227 | 106 | 6 | 17 | 56 | 412 | |

| 24 | 50 | 27,5 | 20 | 17 | 429 | 232 | 112 | 6 | 17 | 60 | 506 | |

| 25 | 50 | 27,5 | 20 | 17 | 446 | 223 | 111 | 6 | 17 | 60 | 526 | |

| 28 | 55 | 27,5 | 20 | 17 | 496 | 197 | 100 | 6 | 17 | 65 | 590 | |

| 30 | 55 | 27,5 | 20 | 17 | 529 | 183 | 100 | 6 | 17 | 65 | 632 | |

| 32 | 60 | 27,5 | 20 | 17 | 749 | 228 | 122 | 6 | 17 | 73 | 899 | |

| 35 | 60 | 27,5 | 20 | 17 | 815 | 208 | 121 | 6 | 17 | 73 | 983 | |

| 38 | 65 | 27,5 | 20 | 17 | 1101 | 238 | 139 | 6 | 17 | 81 | 1334 | |

| 40 | 65 | 27,5 | 20 | 17 | 1154 | 225 | 139 | 6 | 17 | 81 | 1404 | |

| 42 | 75 | 33,5 | 24 | 20 | 1768 | 266 | 149 | 8 | 41 | 95 | 2158 | |

| 45 | 75 | 33,5 | 24 | 20 | 1886 | 247 | 148 | 8 | 41 | 95 | 2312 | |

| 48 | 80 | 33,5 | 24 | 20 | 2004 | 231 | 138 | 8 | 41 | 100 | 2466 | |

| 50 | 80 | 33,5 | 24 | 20 | 2082 | 221 | 138 | 8 | 41 | 100 | 2568 | |

| 55 | 85 | 33,5 | 24 | 20 | 2656 | 233 | 151 | 8 | 41 | 108 | 3296 | |

| 60 | 90 | 33,5 | 24 | 20 | 2881 | 212 | 142 | 8 | 41 | 113 | 3596 | |

| 65 | 95 | 33,5 | 24 | 20 | 3550 | 223 | 153 | 8 | 41 | 121 | 4452 | |

| 70 | 110 | 39,5 | 28 | 24 | 5432 | 245 | 156 | 10 | 83 | 141 | 6844 | |

| 75 | 115 | 39,5 | 28 | 24 | 5795 | 228 | 149 | 10 | 83 | 145 | 7333 | |

| 80 | 120 | 39,5 | 28 | 24 | 6156 | 213 | 142 | 10 | 83 | 150 | 7822 | |

| 85 | 125 | 39,5 | 28 | 24 | 7447 | 228 | 155 | 10 | 83 | 159 | 9498 | |

| 90 | 130 | 39,5 | 28 | 24 | 7857 | 214 | 148 | 10 | 83 | 164 | 10057 | |

| 95 | 135 | 39,5 | 28 | 24 | 9298 | 228 | 160 | 10 | 83 | 173 | 11942 | |

| 100 | 145 | 47 | 33 | 26 | 11126 | 227 | 157 | 12 | 145 | 185 | 14335 | |

| 110 | 155 | 47 | 33 | 26 | 12166 | 205 | 146 | 12 | 145 | 195 | 15768 | |

| 120 | 165 | 47 | 33 | 26 | 15085 | 214 | 155 | 12 | 145 | 210 | 19659 | |

| 130 | 180 | 52 | 38 | 34 | 20326 | 188 | 136 | 12 | 145 | 222 | 26621 | |

| 140 | 190 | 52 | 38 | 34 | 23967 | 191 | 141 | 12 | 145 | 237 | 31536 | |

| 150 | 200 | 52 | 38 | 34 | 27893 | 193 | 145 | 12 | 145 | 250 | 36860 | |

| 160 | 210 | 52 | 38 | 34 | 32102 | 196 | 149 | 12 | 145 | 265 | 42594 | |

| 170 | 225 | 60 | 44 | 38 | 39326 | 190 | 144 | 14 | 230 | 281 | 52377 | |

| 180 | 235 | 60 | 44 | 38 | 45262 | 195 | 149 | 14 | 230 | 300 | 60499 | |

| 190 | 250 | 68 | 52 | 46 | 55552 | 177 | 135 | 14 | 230 | 308 | 74504 | |

| 200 | 260 | 68 | 52 | 46 | 62452 | 175 | 135 | 14 | 230 | 322 | 84027 | |

| 220 | 285 | 74 | 56 | 50 | 79874 | 175 | 135 | 16 | 355 | 351 | 108110 | |

| 240 | 305 | 74 | 56 | 50 | 99995 | 184 | 145 | 16 | 355 | 381 | 136082 | |

| 260 | 325 | 74 | 56 | 50 | 122159 | 192 | 153 | 16 | 355 | 412 | 167078 | |

| 280 | 355 | 86,5 | 66 | 60 | 148773 | 168 | 132 | 18 | 485 | 435 | 204423 | |

| 300 | 375 | 86,5 | 66 | 60 | 178553 | 175 | 140 | 18 | 485 | 465 | 246403 | |

| 320 | 405 | 100,5 | 78 | 72 | 246382 | 177 | 140 | 20 | 690 | 502 | 341382 | |

| 340 | 425 | 100,5 | 78 | 72 | 260791 | 166 | 133 | 20 | 690 | 521 | 362719 | |

| 360 | 455 | 116 | 90 | 84 | 336729 | 164 | 130 | 22 | 930 | 555 | 470012 | |

| 380 | 475 | 116 | 90 | 84 | 371687 | 147 | 119 | 22 | 930 | 574 | 522235 | |

| 400 | 495 | 116 | 90 | 84 | 371687 | 147 | 119 | 22 | 930 | 594 | 522235 | |

| 420 | 515 | 116 | 90 | 84 | 432315 | 155 | 126 | 22 | 930 | 625 | 609275 | |

| 440 | 545 | 130 | 102 | 96 | 531403 | 152 | 122 | 24 | 1200 | 657 | 751102 | |

| 460 | 565 | 130 | 102 | 96 | 554016 | 145 | 118 | 24 | 1200 | 677 | 785243 | |

| 480 | 585 | 130 | 102 | 96 | 605396 | 145 | 119 | 24 | 1200 | 702 | 860354 | |

| 500 | 605 | 130 | 102 | 96 | 658967 | 146 | 120 | 24 | 1200 | 727 | 938878 | |

| 520 | 630 | 130 | 102 | 96 | 699186 | 143 | 118 | 24 | 1200 | 754 | 998625 | |

| 540 | 650 | 130 | 102 | 96 | 724367 | 137 | 114 | 24 | 1200 | 774 | 1037033 | |

| 560 | 670 | 130 | 102 | 96 | 799456 | 141 | 118 | 24 | 1200 | 802 | 1147138 | |

| 580 | 690 | 130 | 102 | 96 | 860618 | 141 | 119 | 24 | 1200 | 827 | 1237612 | |

| 600 | 710 | 130 | 102 | 96 | 888410 | 136 | 115 | 24 | 1200 | 846 | 1280288 | |

| 620 | 730 | 130 | 102 | 96 | 952790 | 137 | 117 | 24 | 1200 | 871 | 1375883 | |

| 640 | 750 | 130 | 102 | 96 | 1019329 | 138 | 117 | 24 | 1200 | 897 | 1474892 | |

| 660 | 770 | 130 | 102 | 96 | 1088021 | 138 | 118 | 24 | 1200 | 922 | 1577315 | |

| 680 | 790 | 130 | 102 | 96 | 1118902 | 134 | 115 | 24 | 1200 | 941 | 1625113 | |

| 700 | 810 | 130 | 102 | 96 | 1231849 | 139 | 120 | 24 | 1200 | 973 | 1792404 | |

| 720 | 830 | 130 | 102 | 96 | 1264816 | 135 | 117 | 24 | 1200 | 992 | 1843615 | |

| 740 | 850 | 130 | 102 | 96 | 1340983 | 135 | 118 | 24 | 1200 | 1017 | 1957987 | |

| 760 | 870 | 130 | 102 | 96 | 1419285 | 136 | 119 | 24 | 1200 | 1043 | 2075774 | |

| 780 | 890 | 130 | 102 | 96 | 1476995 | 134 | 118 | 24 | 1200 | 1065 | 2163687 | |

| 800 | 910 | 130 | 102 | 96 | 1535740 | 133 | 117 | 24 | 1200 | 1088 | 2253307 | |

| 820 | 930 | 130 | 102 | 96 | 1619333 | 133 | 117 | 24 | 1200 | 1111 | 2379629 | |

| 840 | 950 | 130 | 102 | 96 | 1705048 | 134 | 118 | 24 | 1200 | 1137 | 2509365 | |

| 860 | 970 | 130 | 102 | 96 | 1792882 | 134 | 119 | 24 | 1200 | 1163 | 2642515 | |

| 880 | 990 | 130 | 102 | 96 | 1882830 | 134 | 119 | 24 | 1200 | 1187 | 2779079 | |

| 900 | 1010 | 130 | 102 | 96 | 1948904 | 133 | 118 | 24 | 1200 | 1209 | 2880649 | |

| 920 | 1030 | 130 | 102 | 96 | 2016005 | 132 | 118 | 24 | 1200 | 1233 | 2983925 | |

| 940 | 1050 | 130 | 102 | 96 | 2111197 | 132 | 118 | 24 | 1200 | 1257 | 3129024 | |

| 960 | 1070 | 130 | 102 | 96 | 2208493 | 132 | 119 | 24 | 1200 | 1283 | 3277538 | |

| 980 | 1090 | 130 | 102 | 96 | 2279745 | 131 | 118 | 24 | 1200 | 1305 | 3387643 | |

| 1000 | 1110 | 130 | 102 | 96 | 2352018 | 130 | 117 | 24 | 1200 | 1326 | 3499454 |

| CAD |

d inch |

D inch |

L inch |

L1 inch |

L3 inch |

T ft-lbs |

pW psi |

pN psi |

DG mm |

TA ft-lbs |

DN min bei Rp0,2 400 N/mm2 inch |

Tmax ft-lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3/4 | 1.850 | 1.083 | 0.787 | 0.669 | 225 | 35000 | 14200 | 6 | 13 | 2.227 | 261 | |

| 1 | 1.969 | 1.083 | 0.787 | 0.669 | 337 | 33000 | 16800 | 6 | 13 | 2.454 | 391 | |

| 1 1/8 | 2.165 | 1.083 | 0.787 | 0.669 | 424 | 30000 | 15600 | 6 | 13 | 2.655 | 492 | |

| 1 3/16 | 2.159 | 1.108 | 0.813 | 0.669 | 445 | 31000 | 17100 | 6 | 13 | 2.702 | 516 | |

| 1 1/4 | 2.362 | 1.083 | 0.787 | 0.669 | 459 | 35000 | 18600 | 6 | 13 | 3.017 | 532 | |

| 1 3/8 | 2.365 | 1.071 | 0.776 | 0.669 | 622 | 32000 | 18700 | 6 | 13 | 3.025 | 722 | |

| 1 7/16 | 2.559 | 1.083 | 0.787 | 0.669 | 748 | 35000 | 19700 | 6 | 13 | 3.318 | 868 | |

| 1 1/2 | 2.559 | 1.083 | 0.787 | 0.669 | 782 | 33500 | 19700 | 6 | 13 | 3.318 | 907 | |

| 1 5/8 | 2.953 | 1.319 | 0.945 | 0.787 | 1273 | 39000 | 21500 | 8 | 30 | 3.926 | 1477 | |

| 1 11/16 | 2.953 | 1.319 | 0.945 | 0.787 | 1320 | 34000 | 19500 | 8 | 30 | 3.819 | 1531 | |

| 1 3/4 | 2.953 | 1.319 | 0.945 | 0.787 | 1368 | 36000 | 21400 | 8 | 30 | 3.921 | 1587 | |

| 1 7/8 | 3.150 | 1.319 | 0.945 | 0.787 | 1454 | 34000 | 20300 | 8 | 30 | 4.119 | 1687 | |

| 1 15/16 | 3.150 | 1.319 | 0.945 | 0.787 | 1498 | 32000 | 19700 | 8 | 30 | 4.085 | 1738 | |

| 2 | 3.346 | 1.319 | 0.945 | 0.787 | 1808 | 37000 | 22200 | 8 | 30 | 4.493 | 2097 | |

| 2 1/8 | 3.346 | 1.319 | 0.945 | 0.787 | 1919 | 35000 | 22300 | 8 | 30 | 4.499 | 2226 | |

| 2 3/16 | 3.543 | 1.319 | 0.945 | 0.787 | 1971 | 34000 | 21000 | 8 | 30 | 4.678 | 2286 | |

| 2 1/4 | 3.543 | 1.319 | 0.945 | 0.787 | 2023 | 32000 | 20400 | 8 | 30 | 4.639 | 2347 | |

| 2 3/8 | 3.531 | 1.370 | 0.996 | 0.787 | 2127 | 30500 | 20600 | 8 | 30 | 4.636 | 2467 | |

| 2 7/16 | 3.740 | 1.319 | 0.945 | 0.787 | 2497 | 34000 | 22200 | 8 | 30 | 5.022 | 2897 | |

| 2 1/2 | 3.740 | 1.319 | 0.945 | 0.787 | 2556 | 33000 | 22100 | 8 | 30 | 5.015 | 2965 | |

| 2 9/16 | 3.737 | 1.333 | 0.959 | 0.787 | 2617 | 32000 | 22000 | 8 | 30 | 5.004 | 3036 | |

| 2 5/8 | 4.331 | 1.555 | 1.102 | 0.945 | 3775 | 37000 | 22500 | 10 | 61 | 5.840 | 4379 | |

| 2 11/16 | 4.331 | 1.555 | 1.102 | 0.945 | 3866 | 36000 | 22400 | 10 | 61 | 5.832 | 4485 | |

| 2 3/4 | 4.337 | 1.532 | 1.079 | 0.945 | 4017 | 36000 | 22900 | 10 | 61 | 5.881 | 4660 | |

| 2 7/8 | 4.528 | 1.555 | 1.102 | 0.945 | 4175 | 34500 | 22000 | 10 | 61 | 6.063 | 4843 | |

| 2 15/16 | 4.528 | 1.555 | 1.102 | 0.945 | 4262 | 34000 | 22100 | 10 | 61 | 6.071 | 4944 | |

| 3 | 4.724 | 1.555 | 1.102 | 0.945 | 4332 | 33000 | 21000 | 10 | 61 | 6.237 | 5025 | |

| 3 1/8 | 4.724 | 1.555 | 1.102 | 0.945 | 4515 | 31000 | 20600 | 10 | 61 | 6.203 | 5237 | |

| 3 1/4 | 4.921 | 1.555 | 1.102 | 0.945 | 5355 | 33000 | 21800 | 10 | 61 | 6.571 | 6212 | |

| 3 3/8 | 4.921 | 1.555 | 1.102 | 0.945 | 5558 | 34000 | 23400 | 10 | 61 | 6.720 | 6447 | |

| 3 7/16 | 5.118 | 1.555 | 1.102 | 0.945 | 5601 | 32000 | 21500 | 10 | 61 | 6.805 | 6497 | |

| 3 1/2 | 5.118 | 1.555 | 1.102 | 0.945 | 5706 | 31000 | 21200 | 10 | 61 | 6.776 | 6619 | |

| 3 3/4 | 5.305 | 1.594 | 1.142 | 0.945 | 6914 | 34000 | 24100 | 10 | 61 | 7.317 | 8020 | |

| 3 15/16 | 5.708 | 1.852 | 1.301 | 1.024 | 8402 | 33000 | 22800 | 12 | 107 | 7.729 | 9746 | |

| 4 | 5.843 | 1.850 | 1.299 | 1.024 | 8489 | 32000 | 22000 | 12 | 107 | 7.823 | 9847 | |

| 4 7/16 | 6.496 | 1.850 | 1.299 | 1.024 | 10498 | 34000 | 23300 | 12 | 107 | 8.859 | 12178 | |

| 4 1/2 | 6.496 | 1.850 | 1.299 | 1.024 | 10652 | 33000 | 22900 | 12 | 107 | 8.809 | 12356 | |

| 4 15/16 | 7.087 | 2.047 | 1.496 | 1.339 | 14493 | 29000 | 20300 | 12 | 107 | 9.267 | 16812 | |

| 5 | 7.087 | 2.047 | 1.496 | 1.339 | 14672 | 29000 | 20500 | 12 | 107 | 9.293 | 17020 | |

| 5 1/2 | 7.492 | 2.000 | 1.449 | 1.339 | 17804 | 29000 | 21300 | 12 | 107 | 9.934 | 20653 | |

| 6 | 8.268 | 2.047 | 1.496 | 1.339 | 22762 | 30500 | 22200 | 12 | 107 | 11.102 | 26404 | |

| 6 1/2 | 8.858 | 2.362 | 1.732 | 1.496 | 28336 | 29000 | 21300 | 14 | 170 | 11.745 | 32870 | |

| 7 | 9.252 | 2.362 | 1.732 | 1.496 | 33220 | 29000 | 22000 | 14 | 170 | 12.388 | 38535 | |

| 7 1/2 | 9.823 | 2.756 | 2.126 | 1.811 | 41369 | 26500 | 20300 | 14 | 170 | 12.844 | 47988 | |

| 7 7/8 | 10.235 | 2.681 | 2.051 | 1.811 | 46707 | 26500 | 20400 | 14 | 170 | 13.402 | 54180 |

Images & Drawings

Downloads

Product Paper RINGFEDER® Locking Assemblies

Tech Paper Locking Assemblies RINGFEDER® RfN 7012

Instruction Manual Locking Assemblies RINGFEDER® RfN 7012, RfN 7012.2

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

DownloadsSuitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.