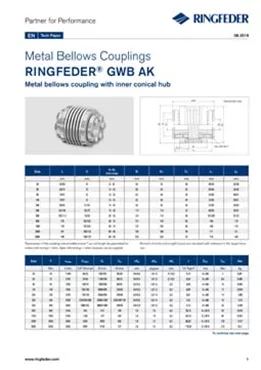

Metal Bellows Couplings GWB AK

Metal bellows couplings from the 'AK' series have been designed especially for the backlash-free transmission of high torques of up to 5,000 Nm. The elements are mounted on driver and driven components with tapered clamping bushings. Depending on the required size, the coupling will be produced with hubs made of aluminum or stainless steel. In addition, AK guarantees for perfect concentric running.

Technical Data & CAD Models

| CAD |

Size

|

L

mm |

d1min

mm |

d1max

mm |

B

mm |

T

Nm |

nmax

1/min |

ΔKa

mm |

ΔKw

Grad |

ΔKr

mm |

DG1

mm |

TA1

Nm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 52 | 9 | 20 | 56 | 36 | 11000 | 0,4 | 1,0 | 0,1 | 4 | 3 | |

| 30 | 60 | 9 | 20 | 56 | 36 | 11000 | 0,5 | 1,5 | 0,2 | 4 | 3 | |

| 60 | 63 | 12 | 25 | 66 | 72 | 9100 | 0,4 | 1,0 | 0,1 | 6 | 8,5 | |

| 60 | 73 | 12 | 25 | 66 | 72 | 9100 | 0,5 | 1,5 | 0,2 | 6 | 8,5 | |

| 80 | 79 | 15 | 35 | 82 | 96 | 7000 | 0,4 | 1,0 | 0,2 | 6 | 10 | |

| 80 | 91 | 15 | 35 | 82 | 96 | 7000 | 0,5 | 1,5 | 0,2 | 6 | 10 | |

| 150 | 79 | 15 | 35 | 82 | 180 | 7000 | 0,4 | 1,0 | 0,2 | 6 | 14 | |

| 150 | 91 | 15 | 35 | 82 | 180 | 7000 | 0,5 | 1,5 | 0,2 | 6 | 14 | |

| 200 | 80 | 15 | 35 | 90 | 240 | 6700 | 0,4 | 1,0 | 0,2 | 6 | 14 | |

| 200 | 80 | 35,1 | 42 | 90 | 240 | 6700 | 0,4 | 1,0 | 0,2 | 6 | 14 | |

| 200 | 93 | 15 | 35 | 90 | 240 | 6700 | 0,5 | 1,5 | 0,2 | 6 | 14 | |

| 200 | 93 | 35,1 | 42 | 90 | 240 | 6700 | 0,5 | 1,5 | 0,2 | 6 | 14 | |

| 300 | 93 | 15 | 42 | 110 | 360 | 5200 | 0,4 | 1,0 | 0,2 | 8 | 18 | |

| 300 | 93 | 30 | 50 | 110 | 360 | 5200 | 0,4 | 1,0 | 0,2 | 8 | 18 | |

| 300 | 104 | 15 | 42 | 110 | 360 | 5200 | 0,5 | 1,5 | 0,2 | 8 | 18 | |

| 300 | 104 | 30 | 50 | 110 | 360 | 5200 | 0,5 | 1,5 | 0,2 | 8 | 18 | |

| 500 | 102 | 24 | 50 | 122 | 600 | 4600 | 0,5 | 1,0 | 0,2 | 8 | 26 | |

| 500 | 102 | 40 | 55 | 122 | 600 | 4600 | 0,5 | 1,0 | 0,2 | 8 | 26 | |

| 500 | 113 | 24 | 50 | 122 | 600 | 4600 | 1 | 1,5 | 0,2 | 8 | 26 | |

| 500 | 113 | 40 | 55 | 122 | 600 | 4600 | 1,0 | 1,5 | 0,2 | 8 | 26 | |

| 800 | 170 | 30 | 60 | 157 | 800 | 3700 | 1 | 1,5 | 0,2 | 16 | 50 | |

| 800 | 170 | 60,1 | 70 | 157 | 800 | 3700 | 1,0 | 1,5 | 0,2 | 16 | 50 | |

| 1400 | 170 | 35 | 60 | 157 | 1400 | 3700 | 1 | 1,5 | 0,2 | 16 | 80 | |

| 1400 | 170 | 60 | 70 | 157 | 1400 | 3700 | 1,0 | 1,5 | 0,2 | 16 | 80 | |

| 3000 | 191 | 50 | 70 | 199 | 3000 | 2800 | 1 | 1,5 | 0,2 | 16 | 130 | |

| 3000 | 191 | 70,1 | 80 | 199 | 3000 | 2800 | 1,0 | 1,5 | 0,2 | 16 | 130 | |

| 5000 | 199 | 60 | 70 | 250 | 5000 | 2800 | 1 | 1,5 | 0,2 | 16 | 210 | |

| 5000 | 199 | 70,1 | 90 | 250 | 5000 | 2800 | 1,0 | 1,5 | 0,2 | 16 | 210 |

| CAD |

Size |

L inch |

d1min inch |

d1max inch |

B inch |

T ft-lbs |

nmax rpm |

ΔKa inch |

ΔKw degree |

ΔKr inch |

DG1 mm |

TA1 ft-lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 2.047 | 0.354 | 0.787 | 2.205 | 27 | 11000 | 0.016 | 1.0 | 0.004 | 4 | 2.2 | |

| 30 | 2.362 | 0.354 | 0.787 | 2.205 | 27 | 11000 | 0.020 | 1.5 | 0.008 | 4 | 2.2 | |

| 60 | 2.480 | 0.472 | 0.984 | 2.598 | 53 | 9100 | 0.016 | 1.0 | 0.004 | 6 | 6.3 | |

| 60 | 2.874 | 0.472 | 0.984 | 2.598 | 53 | 9100 | 0.020 | 1.5 | 0.008 | 6 | 6.3 | |

| 80 | 3.110 | 0.591 | 1.378 | 3.228 | 71 | 7000 | 0.016 | 1.0 | 0.008 | 6 | 7.4 | |

| 80 | 3.583 | 0.591 | 1.378 | 3.228 | 71 | 7000 | 0.020 | 1.5 | 0.008 | 6 | 7.4 | |

| 150 | 3.110 | 0.591 | 1.378 | 3.228 | 133 | 7000 | 0.016 | 1.0 | 0.008 | 6 | 10.0 | |

| 150 | 3.583 | 0.591 | 1.378 | 3.228 | 133 | 7000 | 0.020 | 1.5 | 0.008 | 6 | 10.0 | |

| 200 | 3.150 | 0.591 | 1.378 | 3.543 | 177 | 6700 | 0.016 | 1.0 | 0.008 | 6 | 10.0 | |

| 200 | 3.150 | 1.382 | 1.654 | 3.543 | 177 | 6700 | 0.016 | 1.0 | 0.008 | 6 | 10.3 | |

| 200 | 3.661 | 0.591 | 1.378 | 3.543 | 177 | 6700 | 0.020 | 1.5 | 0.008 | 6 | 10.0 | |

| 200 | 3.661 | 1.382 | 1.654 | 3.543 | 177 | 6700 | 0.020 | 1.5 | 0.008 | 6 | 10.3 | |

| 300 | 3.661 | 0.591 | 1.654 | 4.331 | 266 | 5200 | 0.016 | 1.0 | 0.008 | 8 | 13.0 | |

| 300 | 3.661 | 1.181 | 1.969 | 4.331 | 266 | 5200 | 0.016 | 1.0 | 0.008 | 8 | 13.3 | |

| 300 | 4.094 | 0.591 | 1.654 | 4.331 | 266 | 5200 | 0.020 | 1.5 | 0.008 | 8 | 13.0 | |

| 300 | 4.094 | 1.181 | 1.969 | 4.331 | 266 | 5200 | 0.020 | 1.5 | 0.008 | 8 | 13.3 | |

| 500 | 4.016 | 0.945 | 1.969 | 4.803 | 443 | 4600 | 0.020 | 1.0 | 0.008 | 8 | 19.0 | |

| 500 | 4.016 | 1.575 | 2.165 | 4.803 | 443 | 4600 | 0.020 | 1.0 | 0.008 | 8 | 19.2 | |

| 500 | 4.449 | 0.945 | 1.969 | 4.803 | 443 | 4600 | 0.039 | 1.5 | 0.008 | 8 | 19.0 | |

| 500 | 4.449 | 1.575 | 2.165 | 4.803 | 443 | 4600 | 0.039 | 1.5 | 0.008 | 8 | 19.2 | |

| 800 | 6.693 | 1.181 | 2.362 | 6.181 | 590 | 3700 | 0.039 | 1.5 | 0.008 | 16 | 37.0 | |

| 800 | 6.693 | 2.366 | 2.756 | 6.181 | 590 | 3700 | 0.039 | 1.5 | 0.008 | 16 | 36.9 | |

| 1400 | 6.693 | 1.378 | 2.362 | 6.181 | 1033 | 3700 | 0.039 | 1.5 | 0.008 | 16 | 59.0 | |

| 1400 | 6.693 | 2.362 | 2.756 | 6.181 | 1033 | 3700 | 0.039 | 1.5 | 0.008 | 16 | 59.0 | |

| 3000 | 7.520 | 1.969 | 2.756 | 7.835 | 2213 | 2800 | 0.039 | 1.5 | 0.008 | 16 | 96.0 | |

| 3000 | 7.520 | 2.760 | 3.150 | 7.835 | 2213 | 2800 | 0.039 | 1.5 | 0.008 | 16 | 95.9 | |

| 5000 | 7.835 | 2.362 | 2.756 | 9.843 | 3688 | 2800 | 0.039 | 1.5 | 0.008 | 16 | 155.0 | |

| 5000 | 7.835 | 2.760 | 3.543 | 9.843 | 3688 | 2800 | 0.039 | 1.5 | 0.008 | 16 | 154.9 |

Images & Drawings

Product Characteristics

- Backlash-free transmission of torque

- High torsional stiffness, precision of transmission of rotational angle

- Different torsional stiffness

- Compact design, low moment of inertia

- Metal bellows made of stainless steel

- Simple and safe assembly

- Compensation of radial, axial and angular misalignment

- Free of wear, maintenance-free, no downtimes

- Not sensitive to temperatures between -30°C and + 100°C

- Nominal torques between 0,1 – 5000 Nm

Advantages

- 100% inspection and traceability through individual marking

- Higher torques at same dimensions

- Compact design

- Extended bore ranges

- Customer-specific solutions

- Higher safety in application, e.g. no wrong screw tightening torques

Backlash-free Metal Bellows Couplings are used in the sector of mechanical engineering, where a torque or a rotary motion has to be transmitted from shaft to shaft in highest accuracy of angle.

- Pumps with axial and vertical drives

- High dynamic portal drives

- Spindle lifting units

- Linear units

- Packaging machines

- Machine tools

- Special machines

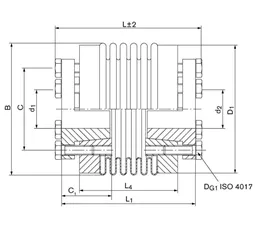

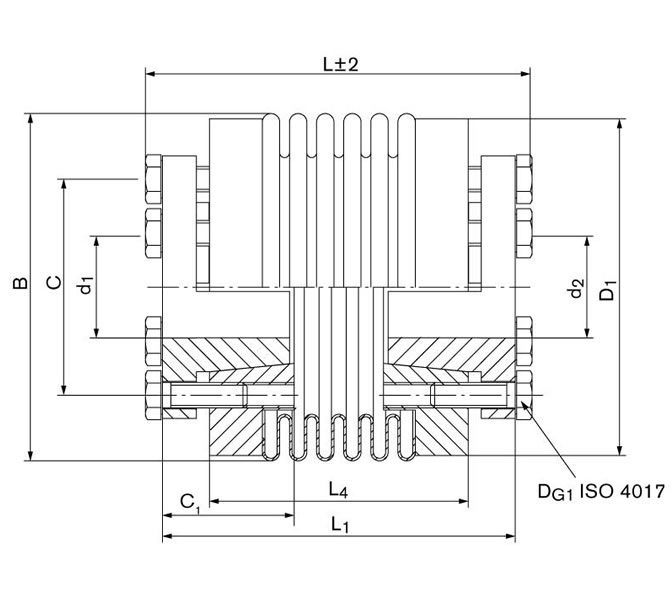

Series AK

- Metal bellows coupling with inner conical hub

Characteristics

- Metal bellows made of stainless steel, conical bushings made of steel

- Hubs up to size 500 made of aluminum, sizes 800 – 5000 hubs made of steel

- The shaft tolerance should be within the fit tolerance “g6” or “h7”

- The contact surfaces have to be free from oil and grease

- Optional special design in stainless steel

Downloads

Product Paper Metal Bellows Couplings RINGFEDER® GWB

Tech Paper Metal Bellows Couplings RINGFEDER® GWB AK

Instruction Metal Bellows Couplings RINGFEDER® GWB

Further downloads including certificates, instruction manuals and product images are available to you in our Download Center:

Downloads