Locking Assemblies RfN 7515

Especially for the bending moment transmission designed 3 part Locking Assembly with reduced stresses in the Locking Assembly itself. Available in sizes 60 to 640 mm.

ℹ This series is also available in true inch sizes.

Technical Data & CAD Models

| CAD |

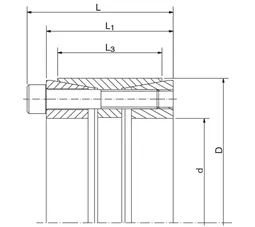

d

mm |

D

mm |

L

mm |

L1

mm |

L3

mm |

T

Nm |

pW

N/mm2 |

pN

N/mm2 |

TA

Nm |

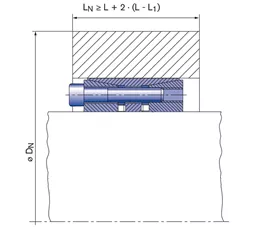

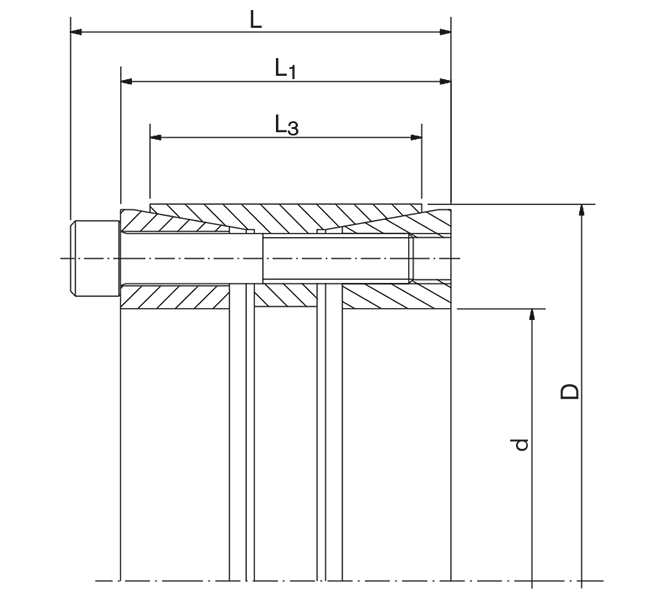

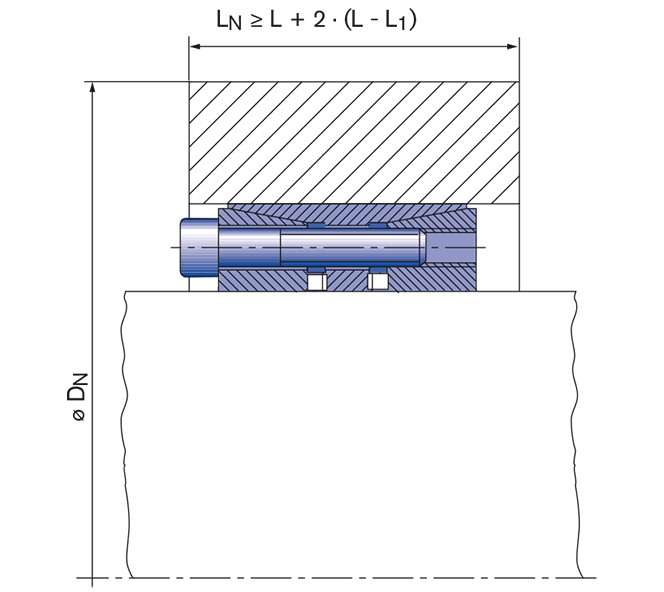

DN min bei Rp0,2 300 N/mm2

mm |

DN min bei Rp0,2 400 N/mm2

mm |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 95 | 58 | 50 | 42 | 4299 | 186 | 118 | 41 | 122 | 115 | |

| 70 | 110 | 70 | 60 | 50 | 7280 | 197 | 125 | 83 | 143 | 134 | |

| 80 | 120 | 70 | 60 | 50 | 10399 | 216 | 144 | 83 | 162 | 150 | |

| 90 | 130 | 70 | 60 | 50 | 12869 | 211 | 146 | 83 | 177 | 163 | |

| 100 | 145 | 82 | 70 | 60 | 18881 | 209 | 144 | 145 | 196 | 182 | |

| 110 | 155 | 82 | 70 | 60 | 20769 | 190 | 135 | 145 | 205 | 191 | |

| 120 | 165 | 82 | 70 | 60 | 24923 | 191 | 139 | 145 | 221 | 205 | |

| 130 | 180 | 91 | 79 | 65 | 34364 | 207 | 150 | 145 | 246 | 227 | |

| 140 | 190 | 91 | 79 | 65 | 39651 | 206 | 152 | 145 | 261 | 241 | |

| 150 | 200 | 91 | 79 | 65 | 42483 | 193 | 144 | 145 | 270 | 250 | |

| 160 | 210 | 91 | 79 | 65 | 48336 | 193 | 147 | 145 | 285 | 264 | |

| 170 | 225 | 106 | 92 | 78 | 65790 | 195 | 147 | 230 | 306 | 283 | |

| 180 | 235 | 106 | 92 | 78 | 69660 | 184 | 141 | 230 | 315 | 292 | |

| 190 | 250 | 116 | 102 | 88 | 78432 | 165 | 125 | 230 | 324 | 303 | |

| 200 | 260 | 116 | 102 | 88 | 92880 | 176 | 135 | 230 | 344 | 320 | |

| 220 | 285 | 126 | 110 | 96 | 116459 | 173 | 133 | 355 | 375 | 350 | |

| 240 | 305 | 124 | 108 | 96 | 169394 | 211 | 166 | 355 | 432 | 394 | |

| 260 | 325 | 127 | 111 | 96 | 183510 | 176 | 141 | 355 | 435 | 404 | |

| 280 | 355 | 131 | 111 | 96 | 230199 | 205 | 162 | 690 | 497 | 456 | |

| 300 | 375 | 131 | 111 | 96 | 263085 | 204 | 163 | 690 | 527 | 482 | |

| 320 | 405 | 156 | 136 | 124 | 350780 | 189 | 150 | 690 | 552 | 510 | |

| 340 | 425 | 156 | 136 | 124 | 372704 | 178 | 143 | 690 | 571 | 529 | |

| 360 | 455 | 177 | 155 | 140 | 487557 | 174 | 137 | 930 | 604 | 562 | |

| 380 | 475 | 177 | 155 | 140 | 514644 | 164 | 132 | 930 | 623 | 581 | |

| 400 | 495 | 177 | 155 | 140 | 595903 | 172 | 139 | 930 | 659 | 612 | |

| 420 | 515 | 177 | 155 | 140 | 682580 | 179 | 146 | 930 | 696 | 644 | |

| 440 | 535 | 177 | 155 | 140 | 715084 | 170 | 140 | 930 | 715 | 663 | |

| 460 | 555 | 177 | 155 | 140 | 747588 | 163 | 135 | 930 | 733 | 683 | |

| 480 | 575 | 177 | 155 | 140 | 812595 | 163 | 136 | 930 | 761 | 708 | |

| 500 | 595 | 177 | 155 | 140 | 846453 | 156 | 131 | 930 | 779 | 727 | |

| 520 | 615 | 177 | 155 | 140 | 985949 | 168 | 142 | 930 | 825 | 765 | |

| 540 | 635 | 177 | 155 | 140 | 1023870 | 162 | 138 | 930 | 844 | 784 | |

| 560 | 655 | 177 | 155 | 140 | 1137633 | 167 | 143 | 930 | 880 | 816 | |

| 580 | 675 | 177 | 155 | 140 | 1178263 | 162 | 139 | 930 | 899 | 835 | |

| 600 | 695 | 177 | 155 | 140 | 1218893 | 156 | 135 | 930 | 917 | 854 | |

| 620 | 715 | 177 | 155 | 140 | 1259522 | 151 | 131 | 930 | 936 | 874 | |

| 640 | 735 | 177 | 155 | 140 | 1300152 | 146 | 128 | 930 | 955 | 893 |

| CAD |

d inch |

D inch |

L inch |

L1 inch |

L3 inch |

T ft-lbs |

Fax lbs |

pW psi |

pN psi |

nSc pcs. |

Schrauben-Norm |

DG mm |

TA ft-lbs |

Gw lbs |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 3/4 | 4.331 | 2.756 | 2.362 | 1.969 | 5400 | 46600 | 28600 | 18200 | 8 | ISO 4762 | 10 | 61 | 6.0 | |

| 2 7/8 | 4.528 | 2.756 | 2.362 | 1.969 | 6100 | 50400 | 29500 | 19900 | 9 | ISO 4762 | 10 | 61 | 6.0 | |

| 2 15/16 | 4.528 | 2.756 | 2.362 | 1.969 | 6500 | 52200 | 29900 | 19900 | 9 | ISO 4762 | 10 | 61 | 6.0 | |

| 3 | 4.724 | 2.756 | 2.362 | 1.969 | 6800 | 54000 | 30400 | 20900 | 10 | ISO 4762 | 10 | 61 | 6.0 | |

| 3 1/8 | 4.724 | 2.756 | 2.362 | 1.969 | 7600 | 57800 | 31200 | 20900 | 10 | ISO 4762 | 10 | 61 | 6.0 | |

| 3 1/4 | 4.724 | 2.756 | 2.362 | 1.969 | 8200 | 60100 | 31200 | 20900 | 10 | ISO 4762 | 10 | 61 | 6.2 | |

| 3 7/16 | 5.118 | 2.756 | 2.362 | 1.969 | 9100 | 62800 | 30800 | 21200 | 11 | ISO 4762 | 10 | 61 | 6.4 | |

| 3 1/2 | 5.118 | 2.756 | 2.362 | 1.969 | 9300 | 63700 | 30800 | 21200 | 11 | ISO 4762 | 10 | 61 | 6.4 | |

| 3 15/16 | 5.709 | 3.228 | 2.756 | 2.362 | 14000 | 85000 | 30400 | 20900 | 10 | ISO 4762 | 12 | 107 | 9.5 | |

| 4 | 5.709 | 3.228 | 2.756 | 2.362 | 14200 | 85000 | 29900 | 20900 | 10 | ISO 4762 | 12 | 107 | 9.7 | |

| 4 3/8 | 6.102 | 3.228 | 2.756 | 2.362 | 15700 | 85900 | 27600 | 19600 | 10 | ISO 4762 | 12 | 107 | 10.4 | |

| 4 7/16 | 6.496 | 3.228 | 2.756 | 2.362 | 16200 | 87300 | 27600 | 20200 | 11 | ISO 4762 | 12 | 107 | 10.6 | |

| 4 1/2 | 6.496 | 3.228 | 2.756 | 2.362 | 16700 | 88600 | 27600 | 20200 | 11 | ISO 4762 | 12 | 107 | 10.6 | |

| 4 3/4 | 6.496 | 3.228 | 2.756 | 2.362 | 18900 | 94900 | 27900 | 20200 | 11 | ISO 4762 | 12 | 107 | 11.2 | |

| 4 15/16 | 7.087 | 3.583 | 3.110 | 2.559 | 22200 | 107300 | 29100 | 21800 | 14 | ISO 4762 | 12 | 107 | 13.0 | |

| 5 | 7.087 | 3.583 | 3.110 | 2.559 | 23300 | 111300 | 29300 | 21800 | 14 | ISO 4762 | 12 | 107 | 13.2 | |

| 5 7/16 | 7.480 | 3.583 | 3.110 | 2.559 | 28600 | 125700 | 29900 | 22100 | 15 | ISO 4762 | 12 | 107 | 15.2 | |

| 5 1/2 | 7.480 | 3.583 | 3.110 | 2.559 | 29200 | 127100 | 29900 | 22100 | 15 | ISO 4762 | 12 | 107 | 15.4 | |

| 5 15/16 | 7.874 | 3.583 | 3.110 | 2.559 | 31700 | 128000 | 28000 | 20900 | 15 | ISO 4762 | 12 | 107 | 15.9 | |

| 6 | 8.268 | 3.583 | 3.110 | 2.559 | 32400 | 129300 | 28000 | 21400 | 16 | ISO 4762 | 12 | 107 | 16.1 | |

| 6 7/16 | 8.858 | 4.173 | 3.622 | 3.071 | 40200 | 149300 | 28200 | 21400 | 15 | ISO 4762 | 14 | 170 | 19.8 | |

| 6 1/2 | 8.858 | 4.173 | 3.622 | 3.071 | 42300 | 155400 | 28200 | 21400 | 15 | ISO 4762 | 14 | 170 | 20.9 | |

| 6 15/16 | 9.252 | 4.173 | 3.622 | 3.071 | 50400 | 174100 | 27500 | 20500 | 15 | ISO 4762 | 14 | 170 | 25.1 | |

| 7 | 9.252 | 4.173 | 3.622 | 3.071 | 50800 | 174100 | 27200 | 20500 | 15 | ISO 4762 | 14 | 170 | 25.4 | |

| 7 1/4 | 9.843 | 4.567 | 4.016 | 3.465 | 54100 | 179000 | 25700 | 18200 | 16 | ISO 4762 | 14 | 170 | 28.4 | |

| 7 7/16 | 9.843 | 4.567 | 4.016 | 3.465 | 57200 | 184400 | 24300 | 18200 | 16 | ISO 4762 | 14 | 170 | 32.0 | |

| 7 1/2 | 9.843 | 4.567 | 4.016 | 3.465 | 58400 | 186900 | 24100 | 18200 | 16 | ISO 4762 | 14 | 170 | 32.6 | |

| 7 15/16 | 10.236 | 4.567 | 4.016 | 3.465 | 70000 | 211400 | 25600 | 19600 | 18 | ISO 4762 | 14 | 170 | 34.8 |

Images & Drawings

Product Characteristics

- Precision Locking Assembly for transmission of torques, axial forces and special optimised for the transmission of bending moments, with special requirements to the true running of the clamped pieces.

- Special features - Through the long and flat cones one Locking Assembly RfN 7515 can transmit torques and axial forces and bending loads. During mounting occurs a slight axial movement from Locking Assembly and hub.

- Bending moment and radial loads – combined loads can be transmitted (Please contact our technical department for assistance).

- Excellent centering ability – with a relatively wide design.

Example applications:

- belt drums

- gear wheels

Mounting of Locking Assembly

The values for T, Fax, pW and pN apply to Locking Assemblies installed in oiled condition.

Surface finishes

For shafts and hub bores Ra ≤ 1,6 μm

Tolerances

We recommend the following mounting tolerances

Shaft: h8; Hub: H8

Change of screw tightening torques

A reduction of the contact pressures and the transmission values by reducing the tightening torque of the screws is possible. the admissible lower limit results from the multiplication of the TA values of the above table by 0,8. There is an approximate linear relationship between T, TA , Fax, pW and pN.

Suitable Industry Solutions

Your Contact to Us

You like to have specific questions, require technical support or you are interested in a customized solution? Our experts in Engineering and Sales are more than happy to assist you. We look forward to your inquiry! Because excellent solutions always start with excellent guidance.

Contact us quickly and easily via our request form, by e-mail or telephone, or also using the "Need Help?" feature at the bottom right of this site.